Timing- & Round Belt Conveyors

Perfect solutions for special transport tasks

Timing- and round belt conveyors are characterised by the particularly quiet and low-wear transport of unit loads.

The compact conveyors can be flexibly adapted to almost any transport task thanks to our modular kit. Whether it’s positive power transmission with timing belts, low-cost alternatives with flat belts or a particularly low product run through the use of round belts – with these conveyors we always offer the perfect solution for special tasks.

Overview

Technical data

The listed technical data are guideline values for standard specifications of our timing- & round belt conveyors. For special requirements, our engineers will be happy to assist you and find a solution for your individual transport task as well.

- Length

- max. 25.000 mm

- Belt width

- 25 / 50 mm

- Conveying load

- max. 250 kg/m (Heavy Duty max. 1.500 kg)

- Drive

- Direct drive, Head drive, Center Drive

- Speed

- max. 65 m/min.

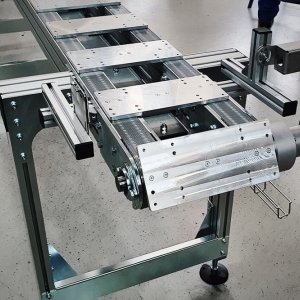

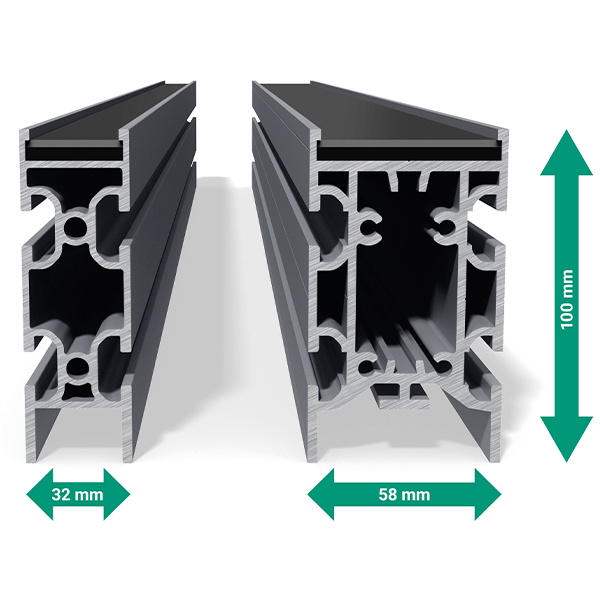

Chassis

The basis

The basis of these conveyors is always a 100 mm high anodised and torsion-resistant aluminium profile. The two continuous profile grooves on each side offer practical options for installing attachments such as supports, side guides or sensors.

ZF25

The ZF25 aluminium profile impresses with its compact design and is the perfect choice for normal loads. It is the basis for 25 mm wide belts or our round belt conveyors.

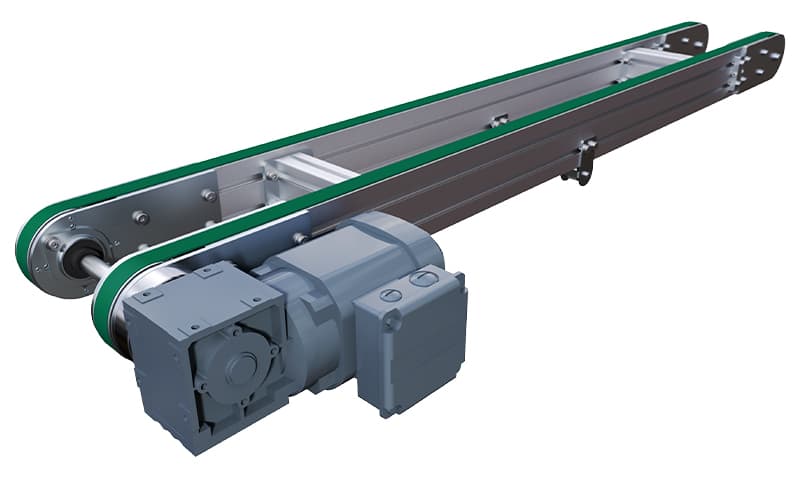

ZF50

For higher product weights, the ZF50 aluminium profile offers a particularly robust base. 50 mm wide belts are used as carrying means.

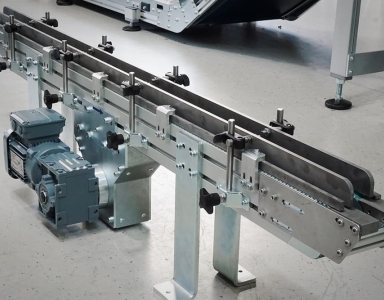

Timing Belt Conveyors

Transporting gently and quietly with timing belt conveyors

It is not without reason that our timing belt conveyors are extremely popular in automation. Whether transporting foods, large, bulky or sensitive products or complicated vehicle parts in the automotive industry – timing belt conveyors always transport your products quietly and gently.

Large weights with ease

Thanks to their positive drive, timing belt conveyors can not only be positioned precisely, but are also capable of conveying heavy weights. For example, a timing belt conveyor in multi-track design can transport several hundred kilos of total weight.

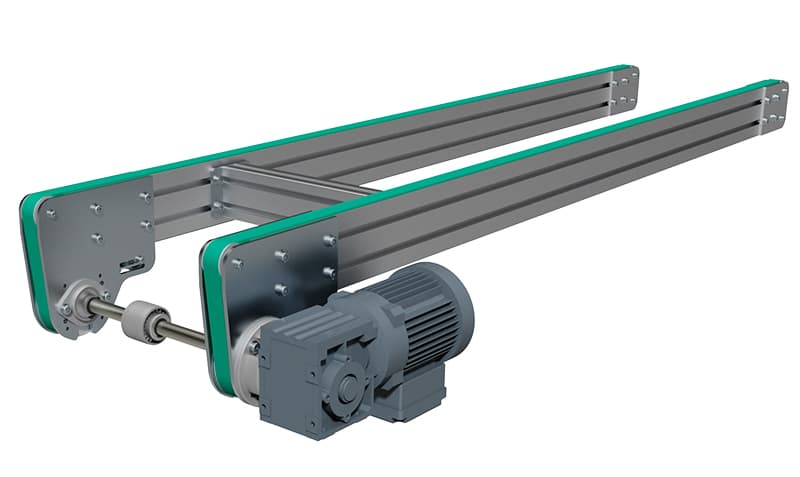

Round belt conveyor

Wide range of possibilities with round belts

Round belt conveyors offer the advantage of extremely low product support as well as very gentle transport.

There is usually a space between the belts in which other components can be installed with good accessibility. The round belt is characterised by its smooth running, tracking accuracy and easy maintenance and cleaning options. They are therefore used particularly frequently in the food industry.

Technical data

- Length

- max. 10.000 mm

- Belt width

- Ø 11 & 13 mm

- Conveying load

- max. 50 kg

- Drive

- Direct drive, Head drive, Center Drive

- Speed

- max. 30 m/min.

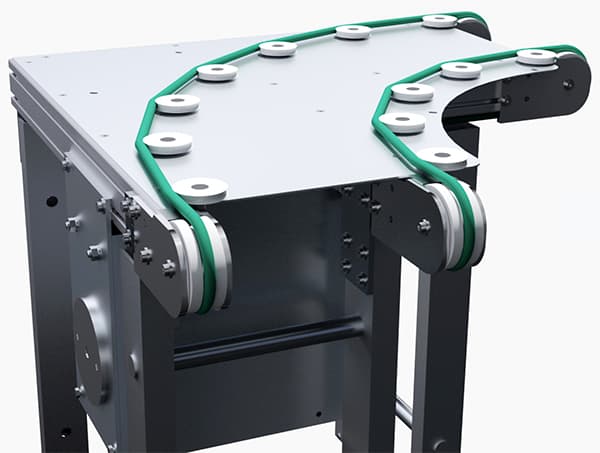

Round belt conveyor

Round belt curve

Round belt curves offer a practical and efficient way of changing direction. With their help, compact interlinking can be easily achieved in the smallest of spaces.

The round belt curve is convincing not least because of its smooth running and easy maintenance and cleaning options. It is therefore used particularly frequently in the food industry and other hygienic areas.

Drive

Unstoppable!

With our efficient drive concepts, our belt conveyors master every application, no matter how heavy, fast or steep it may be.

If a particularly high level of precision or dynamics is required, a stepper motor or servo drive can be used in addition to a three-phase motor. We design the drive according to the installation situation and the desired operating mode. Just as it should be and without any ifs and buts!

Drive types:

- Direct drive

- Head drive

- Center drive

Designs

Clamping & Multitrack Conveyor

Multitrack Conveyor

Our modular system offers you a wide range of solutions to suit the transport task in hand. Belt conveyors with two or more tracks offer enormous potential and transport a wide variety of products safely and effectively. Especially for long goods or large-format products, multi-track systems with many tracks provide a solid basis for process-safe transport. Thanks to its efficient drive system, all tracks are driven synchronously with just one geared motor.

Clamping Conveyor

It is not uncommon for seemingly unsolvable transport tasks to be mastered by using clamping conveyors. They transport products for which ground transport is not available or desired. Therefore, these are particularly well suited for use in labelling and/or inspection tasks. Even difficult transitions from conveyor to conveyor can be overcome with the help of a clamp conveyor. Both tracks can be conveniently adjusted to different product widths by means of a handwheel.

Belts

Variety for every application

The transport belt is the direct connection between your products and the conveyor. The available properties, such as stowage, cut resistance or portability, are almost limitless.

In the case of toothed belts, the profile shape can also be selected to ensure the best possible power transmission. Thanks to the many years of experience of our employees, we always keep an overview and select the optimum conveyor belt for your application.

Equipment

Product holders & carriers

Belt conveyors enable particularly gentle parts transport as there are no interfering edges.

In order to meet the individual requirements of the industry, we offer additional accessories and equipment. Depending on the required transport task, a wide variety of product holders and carriers can be mounted on the belts. For example, bulky parts such as bumpers, profiles, dashboards, panels, stamped parts, trays, moulds and much more can be easily transported.

Of course, active add-on parts such as stoppers, switches, pushers and much more are also available! Please contact us, we will be happy to advise you!

Accessories

Lateral guide & Supports

Lateral guide

Rigid or adjustable, straight or angled, our modular system offers a wide range of different product guides. Moreover, we manufacture lateral guides which enable the adjustment of the clear width and the guiding height. Whatever conditions you impose on use, we’ll design lateral guides precisely according to your product-specific requirements.

Ausführungen:

- Rigid or adjustable

- Straight or angled

- in desired height

- Height and width adjustable

- Stainless steel construction

- special supports to fit your needs

Supports

Our conveyors are always delivered with a stable base frame, manufactured from anodised aluminium profiles. The height is individually adjusted to the requirements, and can also be seamlessly adjusted +/- 50 mm after delivery. We’re also happy to advise you in terms of ergonomics for the design of the base frame.

Versions:

- Supports with machine feet (fixed)

- with swivel castors

- pivoting supports

- height adjustable supports

- compact central support

- slim two-legged supports

- Stainless steel construction

- special supports to fit your needs