Workpiece Carrier Systems

The perfect workpiece carrier system for linear product transport

As we understand precisely the tasks of today, and always have an eye on the demands of tomorrow, we are always one step ahead with the easyflow... workpiece transport system.

The modular design, combined with tailored solutions, guarantees outstanding alignment of the easyflow... system to the transport task assigned.

easyflow... allows you to transport the workpiece carriers clocked through your production or with accumulation functionality. For use as a clocked conveyor, the workpiece carrier is screwed on in a form-fitting manner. In the version with accumulation functionality, the special accumulation roller chains guarantee rolling removal of the workpiece carriers, and thus very low accumulation pres-sure in the system.

Overview

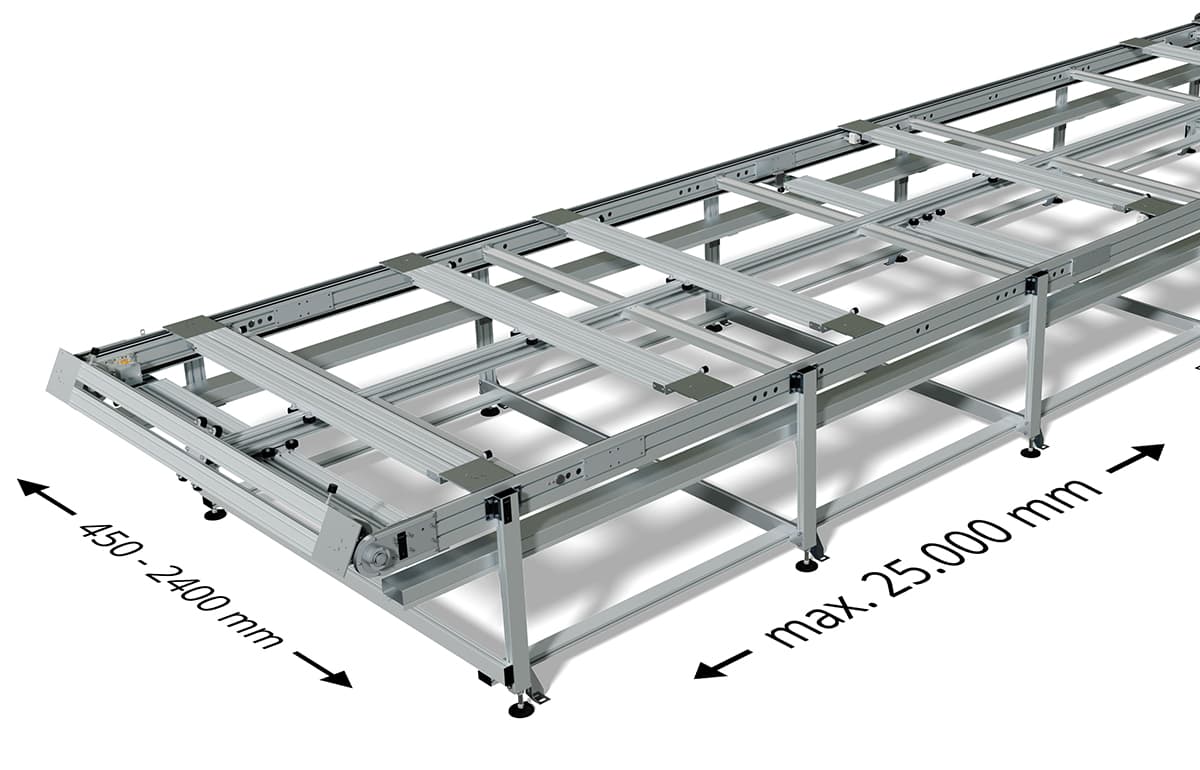

Tchnical data

The technical data listed are guide values for standard specifications. Our engineers will be happy to assist you with special requirements and will also find a solution for your special transport task.

- Length

- max. 30.000 mm

- Usable width

- L = max. 450 mm x W = 2.400 mm/dd>

- Conveying load

- 50 kg (p. Workpiece carrier)

- Drive

- Direct drive

- Speed

- max. 18 m/min.

One Kit

Many possibilities

Thanks to the modular design, numerous add-on parts and components are available for planning the easyflow... workpiece carrier system.

This is how we implement complex systems in the shortest possible time in order to solve your individual transport task. Last but not least, the standardized modules guarantee problem-free expansion of the easyflow... even years later.

The section modules such as stoppers, indexing stations, sensors and solutions for manual workstations are just as modular in structure as the seemingly endless possibilities for designing the workpiece carrier itself.

An extensive selection of track components from the easyflow... modular system is also available for digital factory planning via the Visual Components software. Learn more

Product examples

Thanks to the comprehensive modular system, easyflow has a large number of practical components to optimize your production. Whether clocked or accumulating functionality, with stoppers and indexers through to solutions for manual workstations with complex housings - the possibilities are almost unlimited. We plan and construct easyflow... always suitable for the transport task at hand.

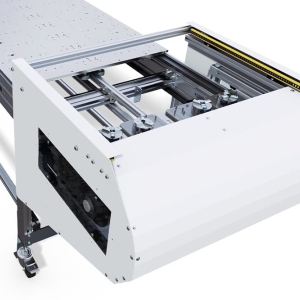

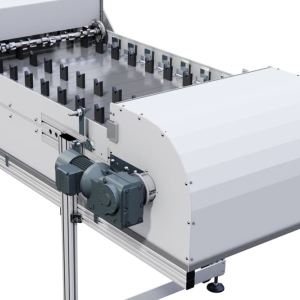

Chassis & Drive

The Basis

Drive

Two accumulation roller chains are positively driven. Various motor types and designs are available to drive the easyflow…. The conveying speed is individually adjusted to the desired cycle time. Optionally, the drive motor can be equipped with a thermal sensor or winding protection contact and various plug connections.

Deflection

easyflow... is equipped with a fully automatic chain tensioning system. The compact unit is fully integrated into the chassis and the chain tension can be checked externally at any time using an optical display.

Positioning

Stop and index

Stoppers

easyflow... is equipped with pneumatic or electric stoppers for stopping and separating. They stop the workpiece carriers with a positioning accuracy of +/- 0.5 mm. The stoppers can be equipped with additional damping units to stop heavy product weights gently. The position and number of the stoppers are designed individually according to your wishes and subsequent relocation is also possible without any problems.

Indexing station

If the positioning accuracy provided by the stopper is not sufficient, an indexing station is used. Indexing (staking out) achieves a positioning accuracy of +/- 0.15 mm in the X and Y direction.

Lift indexing station

By using a lift indexer, the WT is also lifted off the chain and positioned exactly in the Z-direction. Due to the lack of contact with the accumulation roller chains, the WT is also provided vibration-free.

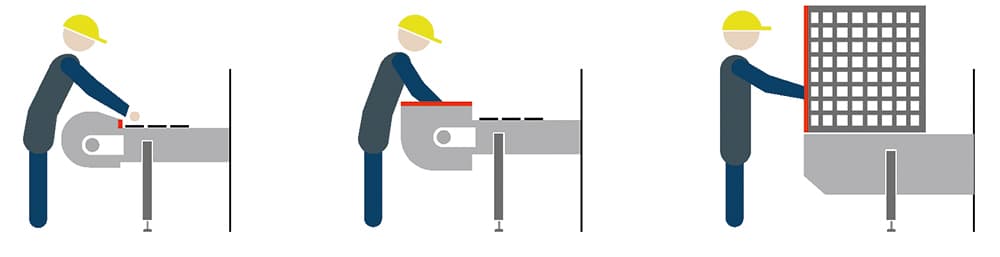

Housing & Workstations

Individual and safe

The easyflow... modular system always offers the optimum housing in the area of the deflection. It is individually adapted to the industrial environment and the desired format. easyflow... also always offers the right protective housing for manual workstations in the deflection area. Ergonomically designed and equipped with a pendulum flap and light grid as required.

Concepts for manual work stations on the front

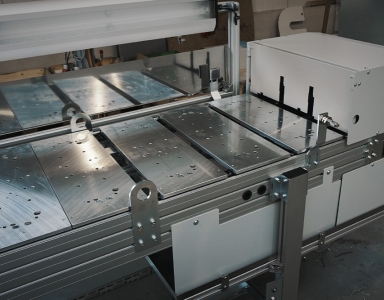

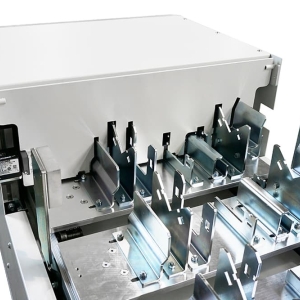

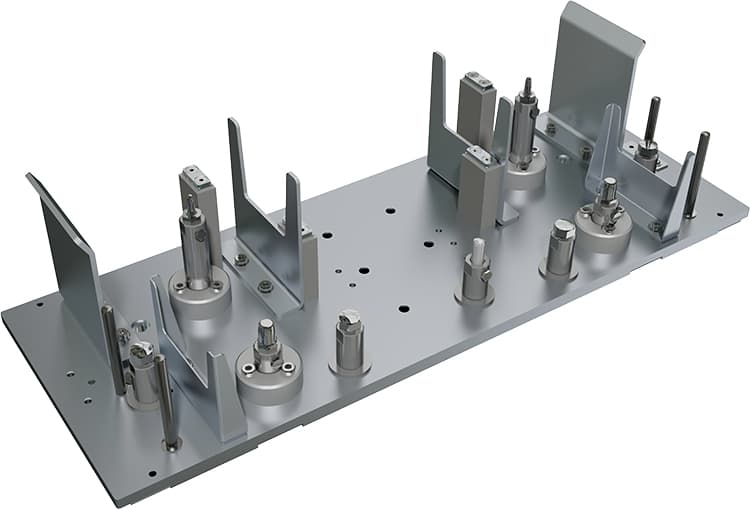

Workpiece Carrier

High End

The workpiece carrier can be as individual and complex as the conveyor system itself.

easyflow… enables robust, precise and gentle product transport thanks to the workpiece carrier. The special mounts are mounted on the base bodies. In this way, even "complicated" products or workpieces can be transported in a reproducible manner. This also provides the prerequisite for exact positioning on robots, test systems or similar units. System width: 450 - 2400 mm

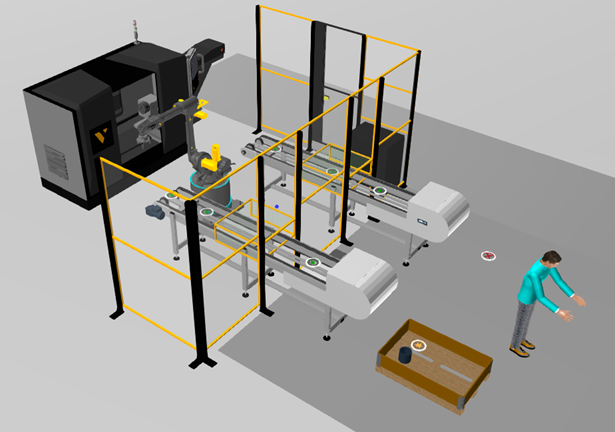

Digital factory planning

Start your digital factory planning now with the easyflow... workpiece carrier system and Visual Components.

Whether indexed or accumulating, the easyflow... workpiece carrier system offers users of the Visual Components software an efficient layout design option for linear product transport. In addition to the dimensions, stoppers and indexing stations as well as safety-relevant components such as enclosures can be planned and integrated into the layout.

For more information visit the Website of Visual Components and find out what possibilities the software might have for your digital factory planning.