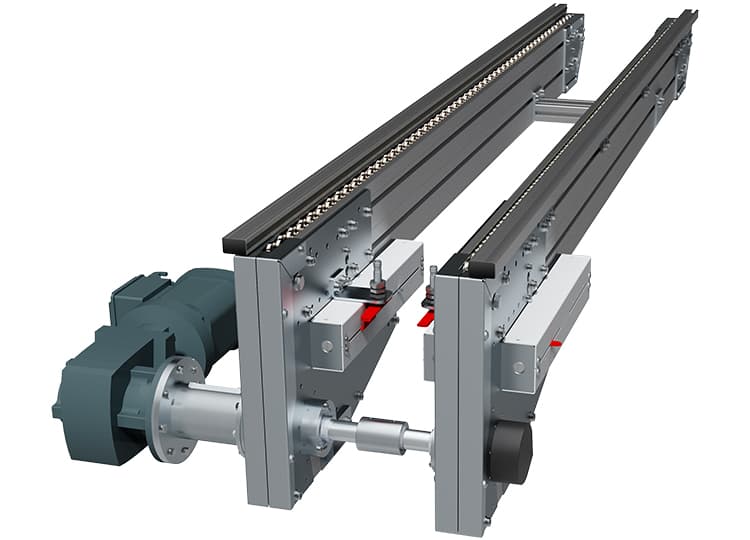

Accumulating Roller Chain Conveyor

Easy low pressure accumulation transport

On accumulation roller chains, you not only transport your products easily and safely through your production, but also with low accumulation pressure.

Accumulation roller chain conveyors show their advantages when low accumulation pressure and gentle product transport is required. From the infeed point to the outfeed side, the technology impresses with an extremely low product buildup of the conveyed material. The free space between the conveyor tracks offers maximum flexibility in the arrangement of stop and processing positions. In addition, our accumulation roller chain conveyors are extremely resistant to wear and are ideally suited for transporting even large loads.

Übersicht

Technische Daten

The technical data listed are guide values for standard specifications of our accumulating roller chain conveyors. For special requirements, our engineers will be happy to assist you and find a solution also for your particular transport task.

- Length

- max. 25.000 mm

- Belt width

- min. 300 mm — max. 2.500 mm

- Conveying load

- max. 1.000 kg

- Drive

- Direct drive, Head drive, Center drive

- Speed

- max. 25 m/min.

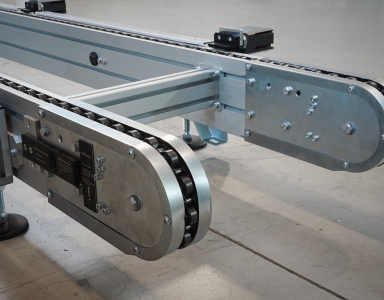

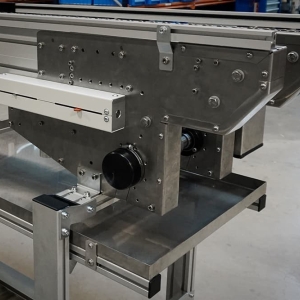

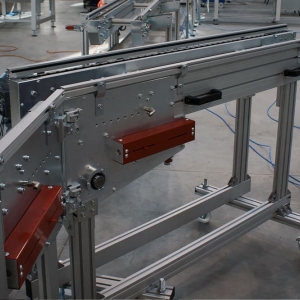

Chassis

The Basis

Two parallel torsionally rigid anodized aluminum profiles form the chassis and thus the basis of our accumulating roller chain conveyors.

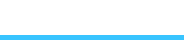

Inside the aluminum profile frame, the accumulation roller chains are guided on low-wear plastic glide bars and returned safely inside the carrier profile, protected from dirt and interference. The design ensures smooth running even in accumulation operation and even when transporting heavy weights. The lateral profile grooves allow easy attachment of add-on parts such as supports, side guides or sensors.

In addition to the standard design, our modular construction kit also includes special designs according to the specifications of the automotive industry. A manual track width adjustment is also available.

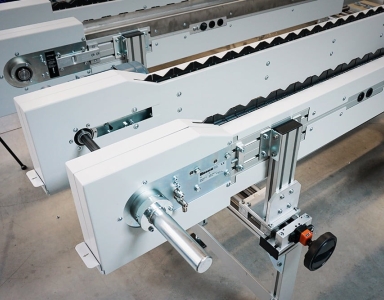

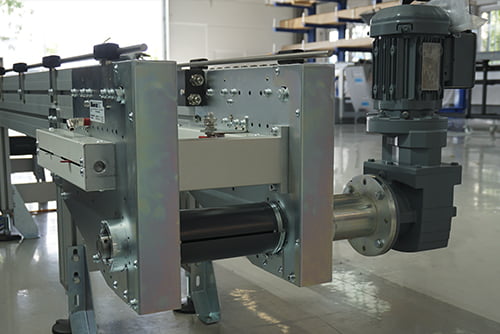

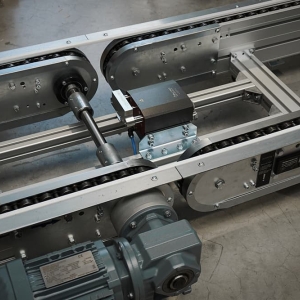

Drives

The drive - Unstoppable!

With our efficient drive concepts, our conveyors master every application, no matter how heavy, fast or steep it may be.

The positive drive concept enables a slip-free chain drive. If required, the motors can be equipped with forced cooling fan, brake, thermal monitoring and additional frequency control. Whether direct or indirect connection between motor and drive roller - we design the drive according to the installation situation and the desired operating mode. Exactly as it should be. In addition to the drive types listed, there is a wide range of special solutions which we will be pleased to design and supply on request.

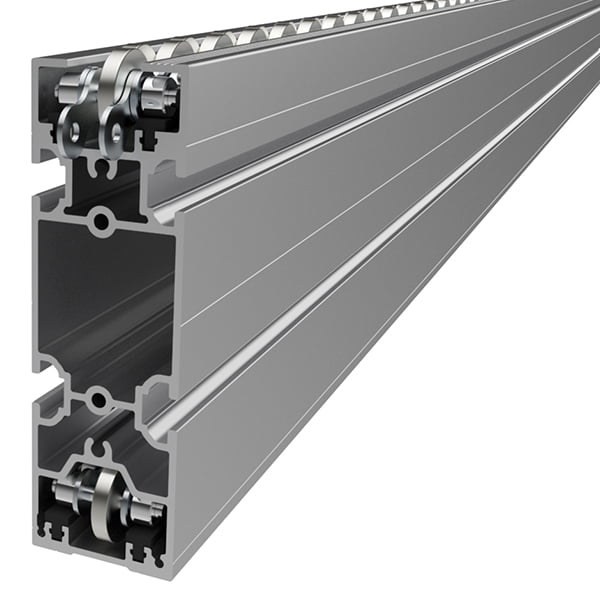

Accumulating roller chain

Robust and highly durable

The centerpiece of this conveyor system is, of course, the accumulation roller chain. It enables accumulation operation with an extremely low accumulation pressure in the system without damaging the transported material.

Accumulating roller chains consist of 1 ½ inch chain links and a so-called accumulating roller at every second pitch. The product or workpiece carriers rest on the larger accumulating rollers and allow the chain to unwind under the transported material in accumulation mode. In addition to various materials, the accumulation roller chains can be equipped with safety clips. This prevents the chain from getting dirty and also protects it from accidental tampering. Depending on the transport task, different sizes, designs and properties are available. Contact us, we will be happy to advise you.

Designs

Flexible and modular

The modular system of our accumulating roller chain conveyors offers various possibilities for the layout and design of your new conveyor system.

The modular construction system of our accumulating roller chain conveyors offers various possibilities for the layout and design of your new conveyor system. Our accumulating roller chain conveyors are already convincing due to their maximum dimensions. Thus, useful widths of 300 to 2,500 mm and total lengths of up to 25,000 mm can be realized without any problems. Furthermore, in addition to a large portfolio of standard components, our modular system also has a low design for transport close to the ground as well as special solutions developed for the automotive industry ready for you.

Accessories

Side guides & supports

Side guides

Our modular system offers you a wide range of different product guides. In addition to the technical versions, we naturally also supply side guides in stainless steel construction for use in hygienic areas.

Versions

- Rigid or adjustable

- Straight or angled

- In desired height

- Height and width adjustable

- Stainless steel construction

- And much more...

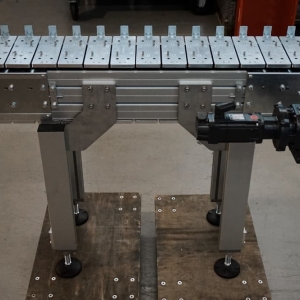

Supports

Our conveyors are always delivered with a stable base frame, manufactured from anodised aluminium profiles. The height is individually adjusted to the requirements, and can also be seamlessly adjusted +/- 50 mm after delivery. We’re also happy to advise you in terms of ergonomics for the design of the base frame.

Versions

- Supports with machine feet (fixed)

- with swivel castors

- Height adjustable supports

- Compact central support

- Particularly slim two-legged supports

- Stainless steel construction

- Special supports can be easily produced

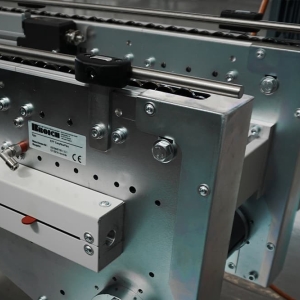

Special Equipment

Stoppers, corner converters, rotary modules etc.

In order to meet the individual requirements for accumulating roller chain conveyors, we offer corresponding special accessories.

With stopper units, targeted stopping of products or product carriers in all weight and speed ranges is possible without any problems. Corner transfer units can be used to transfer product carriers out or in or to transfer them at the end of a conveyor line to a return line. Compared to corner transfer units, rotary modules offer the advantage that the orientation of the products or product carriers remains unchanged when changing direction. In addition, our portfolio offers a large number of other standardized components to solve your special transport task.

Mechanical components and accessories such as enclosures, drive shafts with couplings and oil pans are available, as are automatic chain tensioning and lubrication systems. Based on this conveyor system, a clocked version with fixed product holders and, if required, with an adjustable track width is also available. Thus, the space-saving and efficient system offers versatile possibilities to design your new transport line. Contact us, we will be happy to advise you.