Workpiece carrier systems

Perfect solutions for heavy tasks

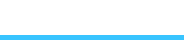

The Skid Conveyor is an extremely robust double-track heavy-duty transport system that has been specially developed for the in-house transportation of heavy loads.

Thanks to its outstanding design, it enables precise and safe transportation even with heavy weights in your production environment.

The skid conveyor system offers an optimal solution for the reliable supply and removal of large load carriers to ensure independent provision and processing in accordance with your operational requirements.

Overview

Technical data

The technical data listed are guide values for standard specifications. For special requirements, our engineers will be happy to assist you and find a solution for your particular transportation task.

- Length

- max. 5.000 mm (Segment length)

- Usable width

- max. 2.400 mm

- Conveying weight

- > 2.000 kg possible

- Speed

- on request

One kit

Many possibilities

With its modular system, the Skid Conveyor heavy-duty transfer system offers the optimum link between logistics and automation.

Thanks to its compact and space-saving design, the skid conveyor system makes efficient use of the available space and opens up almost limitless possibilities for designing layouts. This allows us to implement efficient solutions in the shortest possible time to solve your individual transport task. Last but not least, the standardized modules guarantee problem-free expansion even years later. The track modules are just as modular as the numerous add-on parts. This means that your new interlinking system grows with the task at hand.

Track module

Docking station

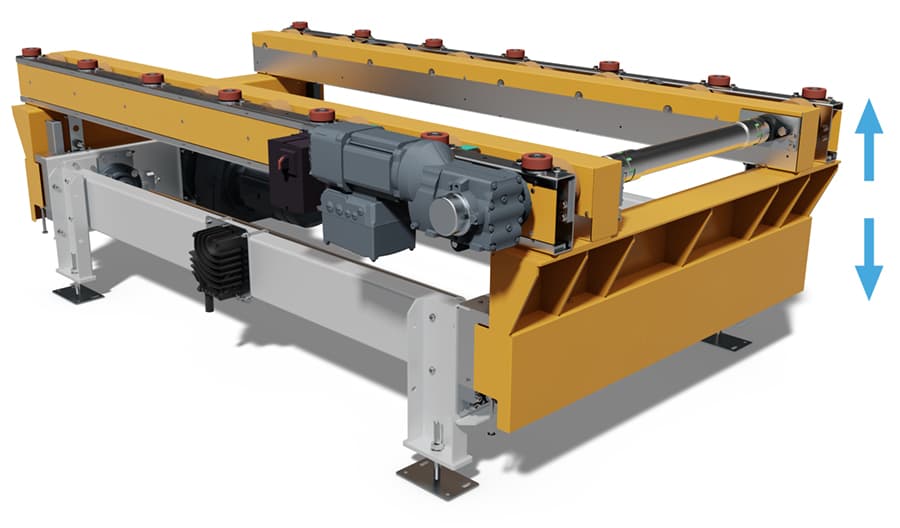

Hub-/Senk-Station

Turning unit

Chassis & Drive

The Basis

The Skid heavy-duty transfer system impresses with its heavy-duty sheet steel chassis, which forms the torsion-resistant base and can easily handle transport weights of up to 2,000 kg.

All skid conveyor modules have a powerful three-phase geared motor that drives the toothed belt drive and drive shaft and provides the necessary torque. The low-maintenance system ensures the safe and precise transportation of large load carriers and enables gentle product transport in your production.

Track module

Modular structure, individual design

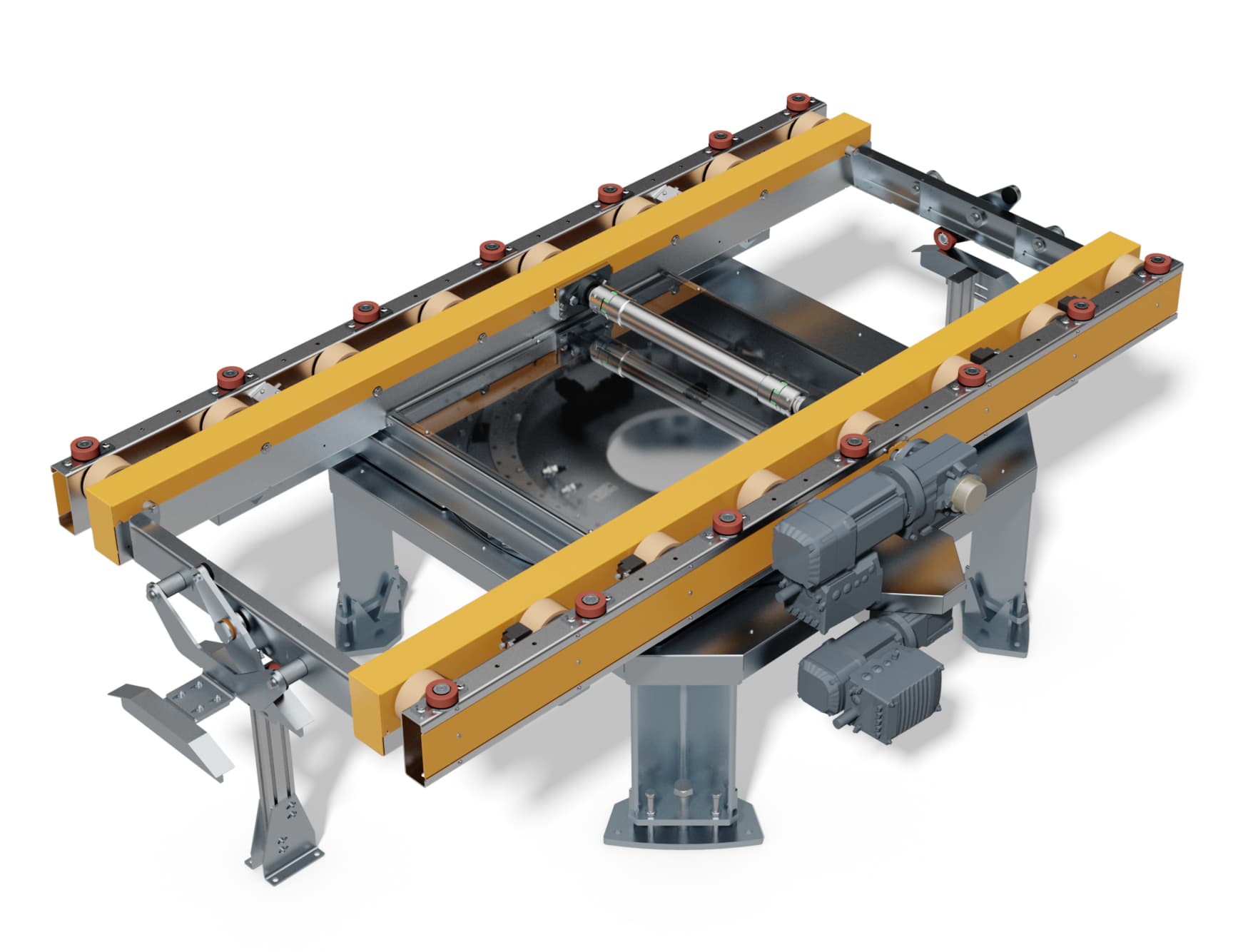

The track modules of the skid conveyor, like all modules of the heavy-duty transfer system, are characterized by their robust and low-maintenance design.

The support rollers and side guide rollers are supplied with a Vulkollan® coating to meet the highest requirements. This high-performance material offers wear protection, damping and contributes to low noise levels. In addition, the toothed belt drive ensures particularly quiet and safe operation.

Docking station

Loading made easy

The docking station enables the manual feeding of workpiece carriers weighing up to 2,000 kg.

Thanks to the durable plastic sliding guides, loading the conveyor line is simple and precise. A mechanical locking system ensures safety, while sensors monitor the loading process. The robust base frame is perfectly protected against damage by a safety housing, which ensures additional safety and durability.

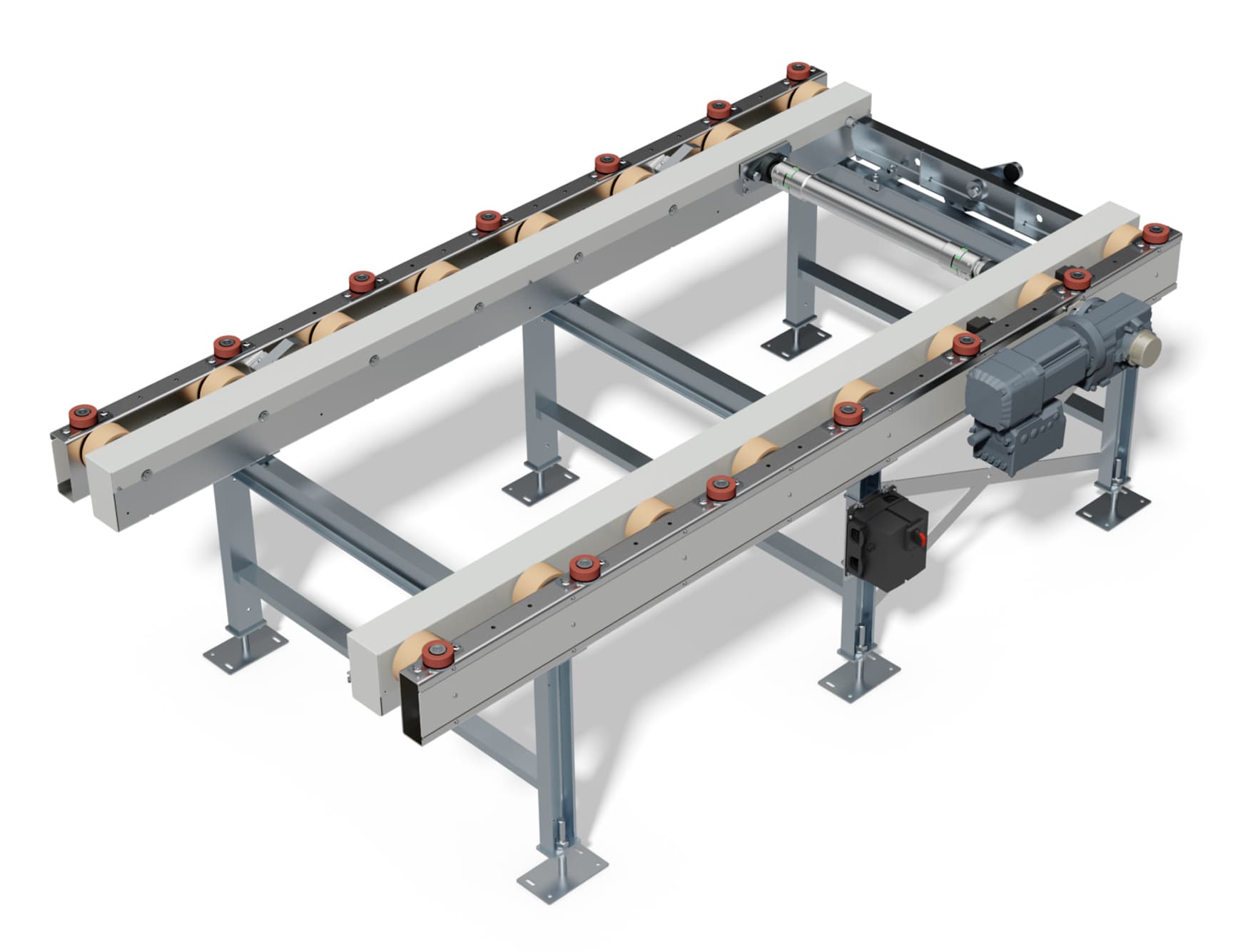

Rotary unit

For maximum planning freedom

The rotating unit of the Skid Conveyor heavy-duty transfer system offers a versatile solution for implementing any route layout.

Thanks to its precise and accurately positioned rotary movement, it enables exact alignment of the workpiece carrier. The rotary unit is equipped with mechanical locking systems on the infeed and outfeed side, which ensures safe use. The compact design of the rotary unit also ensures efficient use of space and offers maximum flexibility when planning your transport route.

Lifting/lowering station

For absolute positioning accuracy

The lifting/lowering station offers precise positioning at testing and processing stations by allowing the workpiece carrier to be placed on an indexing unit.

This ensures absolute positioning accuracy for your workpieces and products for further processing. An almost noiseless lifting/lowering process is guaranteed by the low-maintenance toothed belt drive, which also ensures smooth functionality with this module.

Skid Conveyor

Catalog

All important information can also be found in the Skid Conveyor brochure. (PDF 3,2 MB)