Workpiece carrier systems

The workpiece carrier system for small to medium-sized products

With the easylane... workpiece carrier system, we offer you an extremely robust and compact transport system ready for integration into almost any industrial environment.

The extensive range, consisting of modular assemblies, offers you the possibility to realize complex system concepts in the shortest possible time. Despite the standardized modular system, we also stay flexible in planning. easylane... always offers you a perfect solution, even for your special transport task, from the basic frame to the precisely adapted workpiece carrier.

Overview

Technical Data

The technical data listed are guide values for standard specifications. For special requirements, our engineers will be happy to assist you and find a solution even for your particular transport task.

- Length

- max. 15.000 mm

- Usable width

- max. 265 mm

- Conveying load

- 20 kg p. Workpiece Carrier

- Drive

- Direct drive (single- or double station)

- Speed

- max. 15 m/min.

One Kit

Many possibilities

Like all conveyor systems from Broich Systemtechnik, the easylane... workpiece carrier system is 100% modular.

From individual route planning to electrics and controls, right through to the design of the workpiece carriers, no wishes remain unfulfilled. The extensive range of modular components offers the right solution for every transport task. If our modular system does not provide the right solution, a professional team of engineers is ready to solve your special transport task.

Workpiece carrier

Chassis

Drive station

Double drive station

Stopper

Lift-Indexer

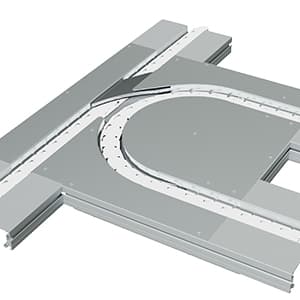

90° Curve

180° Curve

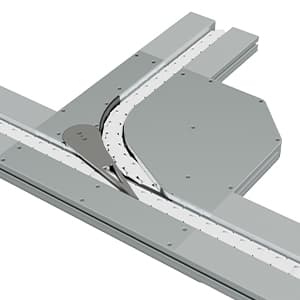

Switch Typ I

Switch Typ II

An extensive selection of track components from the easylane... modular system is also available for digital factory planning via the Visual Components software. Learn more

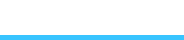

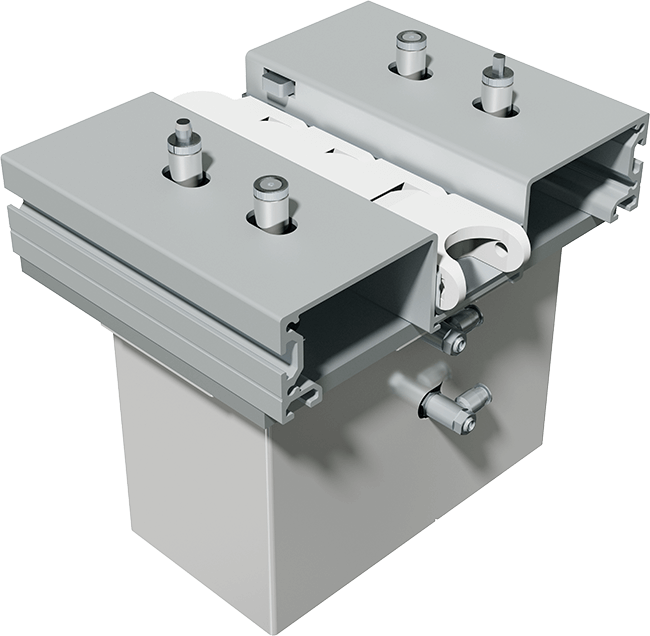

Chassis & Drive

The Basis

Depending on the transport task, various designs and drive types are available for the easylane... workpiece carrier system.

The basis of the system is the aluminum chassis used together with the extremely robust sliding chain and the matching workpiece carriers. Due to the chassis width of 265 mm, you can easily combine easylane... with existing systems of the same design. With product-specific mounts, the workpiece carriers of the easylane... ensure precise and gentle transport of your products.

Product examples

The modular construction kit of the workpiece carrier system easylane... has a wide range of practical components to optimize your production. Whether base frame, chassis and drive stations or stoppers and indexers - the possibilities are almost unlimited. We plan and design easylane... always suitable for the transport task at hand.

Positioning

Stop & Index

Stoppers

For stopping and separating the workpiece carriers, easylane... is equipped with pneumatic, electric or manual stoppers. If required, spring-loaded backstops can fix the workpiece carrier against the conveying direction. For integration into your control system, the stoppers are prepared for interrogation of the stopper position. This can be done either via cylinder switches or proximity switches.

Indexing Station & Lift Indexing Station

If a higher positioning accuracy of the workpiece carrier is required, this is increased to +/-0.15mm with the help of an indexing station. Here, the workpiece carrier is either positioned on the sliding chain or completely lifted out of the conveyor line. The lifting height of the lifting indexing station used is adapted exactly to your requirements.

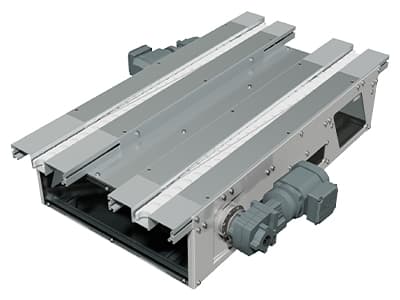

Direction change

Curves & Switches

Complex routes can only be planned and realized through the use of curves and switches.

Curves

The easylane... curve modules offers a cost-effective and space-saving change of direction without a separate drive. In the curve area, the alignment of the workpiece carriers is not changed and an accumulation functionality is possible without any problems. The modular standard curve angles are 90° and 180°. Required special angles are individually designed and manufactured for your requirements. Due to the continuous profile groove, easylane... also offers versatile mounting options in the area of the curves.

Switch

With a switch, easylane... enables the infeed/outfeed of workpiece carriers in main and secondary lines. In this way, individual and complex line layouts can be realized. The switch can be set pneumatically, electrically or manually, whereby no additional drive is required. As with the curve modules, the standard curve angles of our switches are 90° and 180°.

Radius and angle

Our modular system also offers two different variants for the radius of our curve and switch modules with sizes of 150 mm and 225 mm. This allows us to make optimum use of the available installation space and to respond perfectly to your installation situation.

Workpiece carrier

High End

The direct connection between your product and the easylane... transport system is the workpiece carrier.

The workpiece carrier can be as individual and complex as the conveyor itself. The right workpiece carrier is always developed for each product. This ensures that your products pass through production precisely and safely.

The easylane... workpiece carrier enables precise and gentle transport of your products on the sliding chain. The product-specific holders are mounted on the top plate. This enables reproducible transport of "complicated" products or workpieces as well as exact positioning on robots, inspection stations or similar units. The workpiece carriers have wear-resistant chain supports.

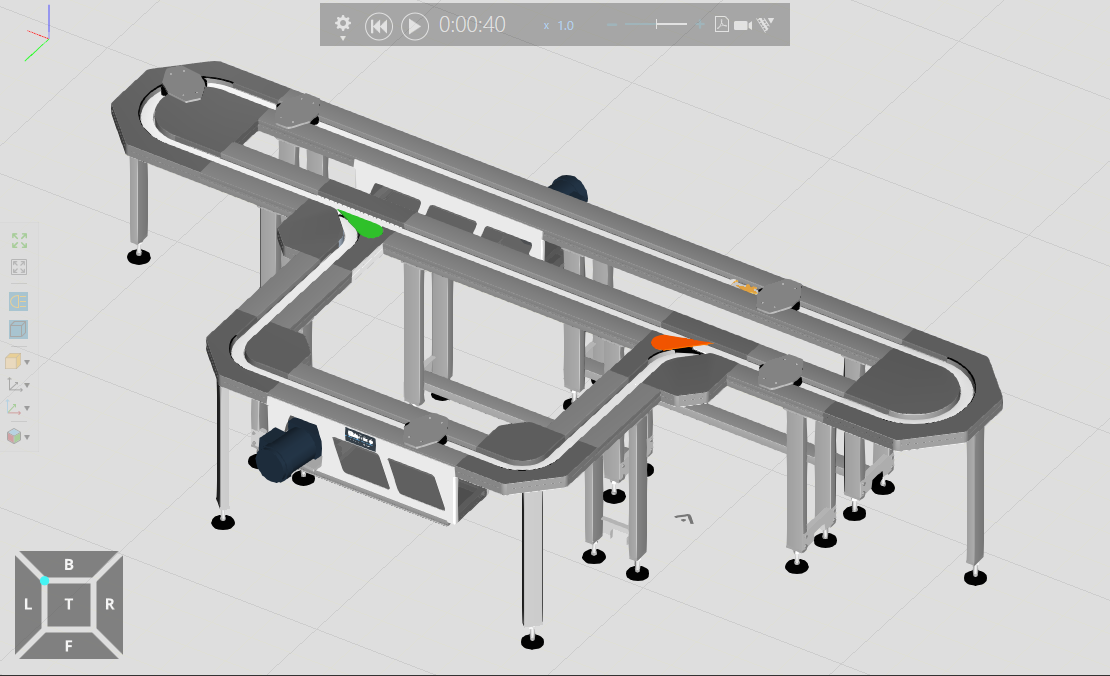

Digital factory planning

Start now with the easylane workpiece carrier system... and Visual Components for your digital factory planning.

Thanks to its modular construction kit, users of the software can use the Visual Components eCatalog to plan their system concepts flexibly and to the full extent with the help of easylane... and simulate transport processes. The selection of different track components with drive stations, curves, switches as well as stoppers, indexing and lifting stations offers endless possibilities for layout design.

For more information visit the Website of Visual Components and find out what possibilities the software might have for your digital factory planning.