Hinge Plate Conveyor

Almost unlimited possibilities

With the SF8 steel hinge plate conveyor, we offer a particularly robust and modular conveyor system suitable for use in a wide variety of industrial environments.

With their hard-wearing steel hinge plate belts, they are ideally prepared for extremely difficult transport tasks and thus convey sharp-edged, heavily soiled, oily or hot goods without any problems. The plate conveyors themselves can be individually configured and our modular construction kit also offers almost all possibilities in terms of design.

Overview

Technical Data

The technical data listed are guide values for standard specifications of our hinge plate conveyors. For special requirements, our engineers will be happy to assist you and find a solution also for your particular transport task.

- Length

- max. 20.000 mm

- Useable width

- min. 100 mm — max. 1.200 mm

- Conveying load

- max. 100 kg/m

- Drive

- Direct drive, head drive

- Speed

- max. 15 m/min.

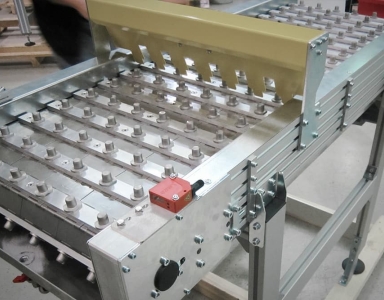

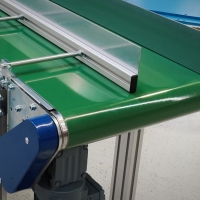

Chassis

The Basis

The chassis of the SF8 is made of a torsion-resistant, anodized aluminum profile frame, which forms the belt bridge and thus the basis of our hinge plate conveyors.

With up to six lateral profile grooves, the aluminum chassis offers a wide range of attachment options for supports, accessories and other equipment components. Thanks to our modular construction kit, various designs and equipment variants are available for hinge plate conveyors. This allows us to realize your new conveyor system in the shortest possible time.

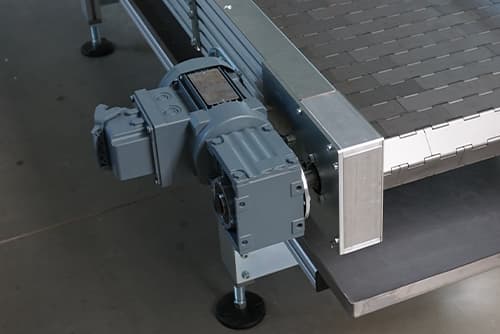

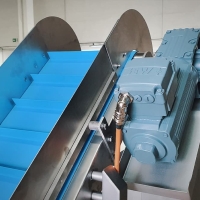

Drive

The drive - Unstoppable!

With our efficient drive concepts, our conveyors master every application, no matter how heavy, fast or steep it may be.

The form-fit drive concept enables a slip-free chain drive with simultaneously laterally stable chain guidance. If required, the motors can be equipped with forced cooling fan, brake, thermal monitoring and additional frequency control. We design the drive according to the installation situation and the desired operating mode. Exactly as it should be. In addition to the drive types listed, there is a wide range of special solutions which we will be pleased to design and supply on request.

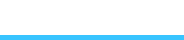

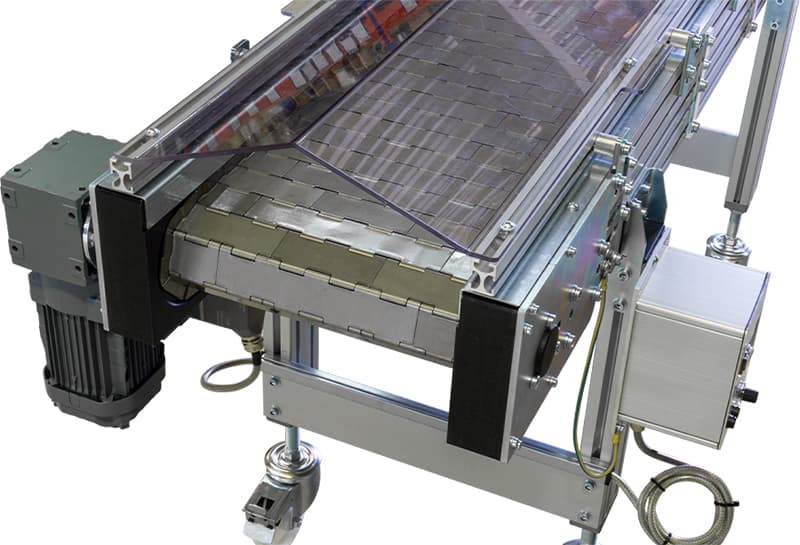

Hinge plate belt

Many possibilities - one goal

The particularly robust hinged-plate belt of the SF8 is the main feature of this conveyor system.

It can withstand the most adverse conditions and can be supplied as standard in flat, dimpled, slotted or perforated versions. It is also possible to attach carriers, side boards and even screw-on options for various product fixtures, depending on the application. Various FDA-approved designs are available for use in hygienic areas. There are countless options available for designing your new hinge plate conveyor, contact us, we will be happy to advise you.

Designs:

- flat / dimpled

- slotted / perforated

- perforated & dimpled

- with cleats

- with side boards

- and much more...

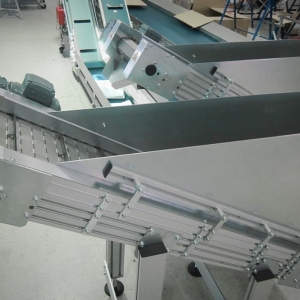

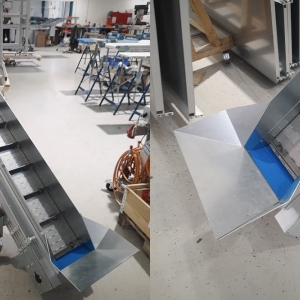

Designs

Always the right design

Our steel hinge plate conveyors do not only transport reliably and safely through your production, they also convince with the possible designs.

From horizontal, inclined or kinked conveyors with negative or positive kink as well as Z-conveyors with both kink variants, our modular system also offers you practically every design in the area of steel hinge plate conveyors.

Designs:

- Horizontal conveyor

- Inclined conveyor

- Kink or L-conveyor

- Z-conveyor

Accessories

Side guides & supports

Side guides

Our modular system offers you a wide range of different product guides. In addition to the technical versions, we naturally also supply side guides in stainless steel construction for use in hygienic areas.

Versions

- Rigid or adjustable

- Straight or angled

- In desired height

- Height and width adjustable

- Stainless steel construction

- And much more...

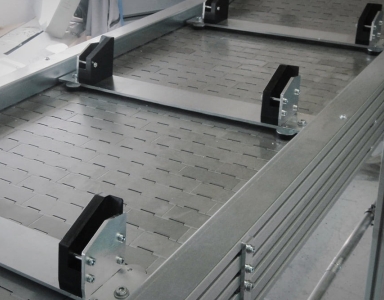

Supports

Our conveyors are always delivered with a stable base frame, manufactured from anodised aluminium profiles. The height is individually adjusted to the requirements, and can also be seamlessly adjusted +/- 50 mm after delivery. We’re also happy to advise you in terms of ergonomics for the design of the base frame.

Versions

- Supports with machine feet (fixed)

- with swivel castors

- Height adjustable supports

- Compact central support

- Particularly slim two-legged supports

- Stainless steel construction

- Special supports can be easily produced

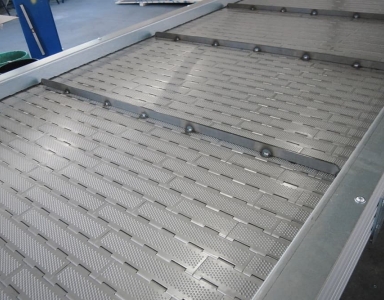

Special Equipment

Bunker, funnel, cover etc.

We offer appropriate accessories in order to satisfy the individual requirements for industrial conveyor systems.

Exit chutes in product-specific variations are available. Standard funnels or special funnels especially designed and manufactured according to customer speci- fications. A belt cover for protecting parts to be transported from dirt or as contact protec- tion in hazardous surroundings.

Of course, active add-on parts such as stoppers, switches, pushers and much more are also available! Please contact us, we’ll be happy to advise you!

Stainless Steel

An essential material

Especially in hygienically sensitive areas, the use of conveyor systems and machines is associated with special challenges.

As a specialist for conveying technology, we naturally also offer you individual solutions when it comes to logistical processing in the food, cosmetics and pharmaceutical industries.

Thanks to our modular construction systems, we can draw on a large portfolio of the most diverse conveyor systems in stainless steel construction. Thanks to many years of experience in the field of stainless steel processing, we can implement systems that meet your special requirements. In this way, we manufacture and supply the right conveyor technology for almost any transport task, and always with an attractive price-performance ratio.