Construction

The name Broich Systemtechnik stands for conveyor technology “Made in Germany”. We have been developing and producing conveyor technology and conveyor systems for industrial transportation tasks for around 20 years.

Today, our design department consists of 16 designers, technical draughtsmen and technical editors. Our work processes are efficient and uncomplicated and our technical equipment is always state-of-the-art. Lean structures ensure an optimum cost-benefit ratio from which our customers benefit. Our design, production and assembly departments work hand in hand in close proximity to each other - this makes communication between the departments much easier. Translated with DeepL.com (free version)

Store, organize and manage

Central data management

A few years ago, we introduced Autodesk Vault for centralized data management in order to be able to use our own modular system more effectively. With the support of Mensch und Maschine, this goal was achieved perfectly. Autodesk Vault is a data management software solution developed specifically for engineering and construction environments. It provides a central database for storing, organizing and managing design data, including 3D models, drawings, assemblies, simulations and documentation.

From centralized data management, access control, revision and approval workflows to data backup and integration with Autodesk products, the software ensures optimal working conditions within the design department. The data vault allows our designers to concentrate on optimizing the design instead of dealing with time-consuming manual processes. Last but not least, this facilitates communication with other departments through to production, delivery and commissioning of a system.

One kit - many possibilities

Modular design

From the very beginning, we have focused on the modular design of our products and have always driven this thinking forward. Over the years, our product portfolio has developed into a huge modular system that enables us to solve almost any industrial transportation task.

Successful standardization, whether belt conveyors, chain conveyors or more complex system concepts such as our workpiece carrier systems, allows us to meet the specific requirements of projects or customers in the shortest possible time. Overall, the modular design gives us improved flexibility, efficiency, standardization, cost efficiency, short production times and greater customer satisfaction. In this way, we help our customers to remain competitive and produce successfully in the long term.

We understand your particular task

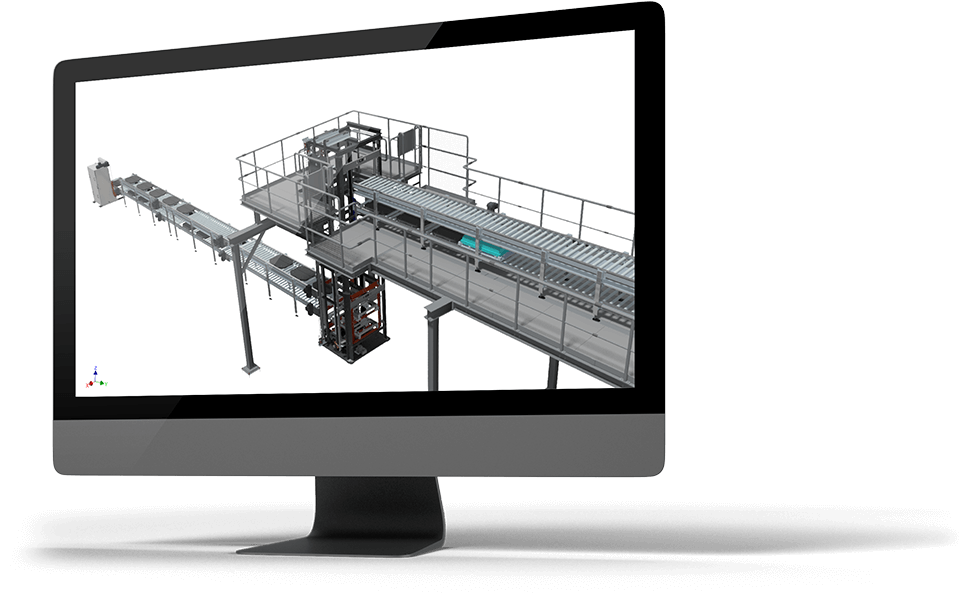

Special systems

Moving, lifting, turning - from chocolates to car batteries weighing several tons in the automotive industry, we are prepared for almost any requirement.

If our modular system does not provide the desired solution, our team of experienced designers is ready to break new ground, find solutions and make possible what may have previously seemed impossible. Especially in the field of automation and automation of production processes, we always have to face new challenges, think outside the box and develop innovative approaches in order to meet the constantly changing requirements.

Developing, testing, checking - we design special solutions with experience and a sure instinct - every day, time and time again! Because it's rarely just a matter of simple transportation “from A to B”. From the installation situation and spatial environment to special safety requirements and cycle time-related specifications, we also understand your particular task and are happy to develop special solutions for you.

Almost unlimited possibilities

Extensions and conversions

In a rapidly changing world, production and automation processes often change too.

One of the major advantages of the modular design of our conveyor technology products is the wide range of options for desired extensions and conversions of existing systems. Here too, our design engineers react quickly and flexibly to your wishes. Extensions or conversions to the routing can usually be implemented without any problems.

Of course, modifications are also possible, for example to the product guides, control processes, retrofitting with the necessary sensors or stopper and/or indexing units - here too, the possibilities are almost limitless. Contact us, we will be happy to advise you on your project.

Solutions for specific requirements

Additive manufacturing

In order to be able to react flexibly to individual requirements and specific customer inquiries, we have our own state-of-the-art 3D printing laboratory.

Thanks to this technology, we can produce customized prototypes, series products and spare parts and thus supply our customers with products that meet their exact requirements in the shortest possible time. In addition, this technology allows us to produce efficiently without the limitations of traditional manufacturing methods, as it supports a wide range of materials and complex geometric shapes.

Particularly in the area of individual product transportation, it often turns out that the proverbial “devil is in the detail”. By using 3D printing technology, we have already been able to overcome numerous challenges in the handling of products in a simple and effective way. This technology enables us to develop customized solutions for specific requirements and thus offer our customers perfect production processes.

Quality feature for our products

Documentation

Technical documentation is an important part of the entire life cycle of our conveyor systems, from planning and design through to commissioning, maintenance and, ultimately, decommissioning.

Here too, we want to ensure that we provide you with comprehensive advice and ultimately deliver high-quality documentation for your new conveyor system. Our experienced team of technical writers creates documentation according to our own standards or, on request, according to customer specifications, whereby the focus is of course always on the benefits for the customer. This includes consideration of customer-specific applications, operating conditions and safety requirements. High-quality documentation is therefore also an integral part of a conveyor system from Broich Systemtechnik and should ultimately serve as a quality feature for our products and help our customers to operate the systems efficiently.

Digital factory planning

Start your digital factory planning now with the easymove... and Visual Components for your digital factory planning.

As the first fully-fledged workpiece carrier system in Visual Components' eCatalog, easymove... significantly expands the possibilities of the software. The extensive selection of track components such as curves, switches, lifts, turning stations as well as stopper and indexing units offer users endless possibilities for layout design.

For more information, visit the Visual Components website and find out what possibilities the software might have for your digital factory planning.