Complex transport tasks with ease

Components

Our modular construction system also supplies an extensive range of standard components for your transport task.

With their help, we are able to design complex layouts and production lines for almost any application in a very short time. Our portfolio ranges from various stopper and indexing units to conveyor systems for vertical product transport to 360° turning stations and push-off modules. The adaptation and combination of the components with various conveying technologies is possible.

Accurate and precise stopping

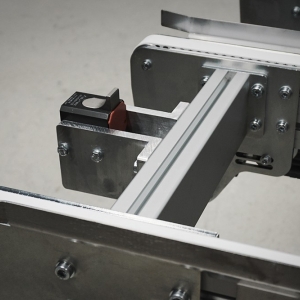

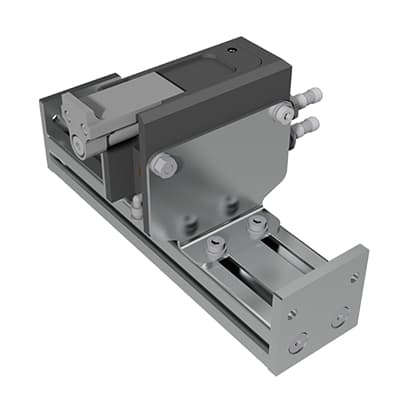

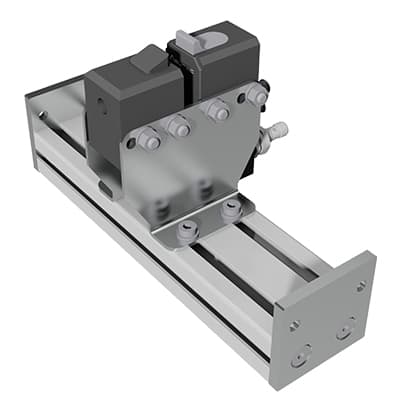

Stoppers

A wide range of different stoppers is available for precise stopping and separation of workpiece carriers or products.

This allows precise and gentle stopping of your products in all weight and speed ranges without any problems. In addition to the usual pneumatic actuation, stoppers are also available in a purely electrical version.

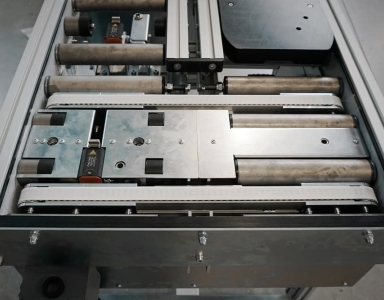

Indexing & Positioning

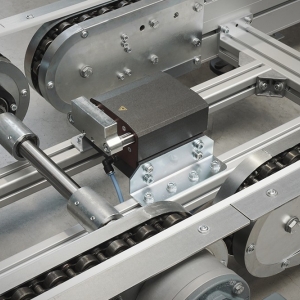

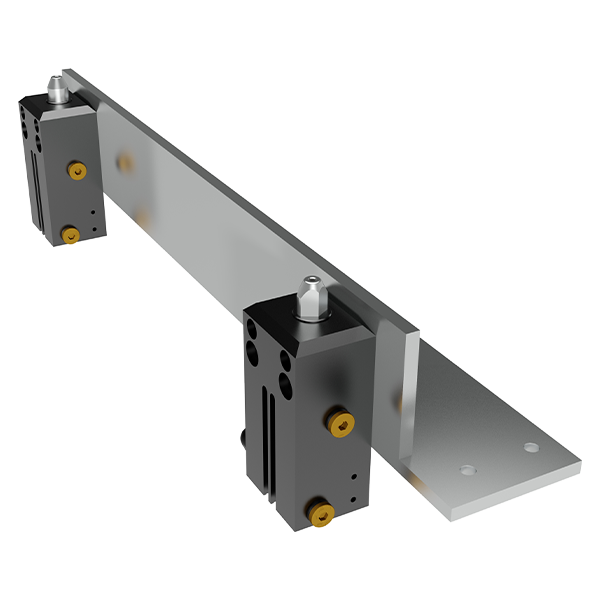

Indexer

Indexing station

If the positioning accuracy is not sufficient due to a stopper, it can be increased to +/-0.1 mm with the help of an indexing station. Indexing stations ensure exact alignment and positioning of your products for precise processing on robots, inspection stations and manual workstations.

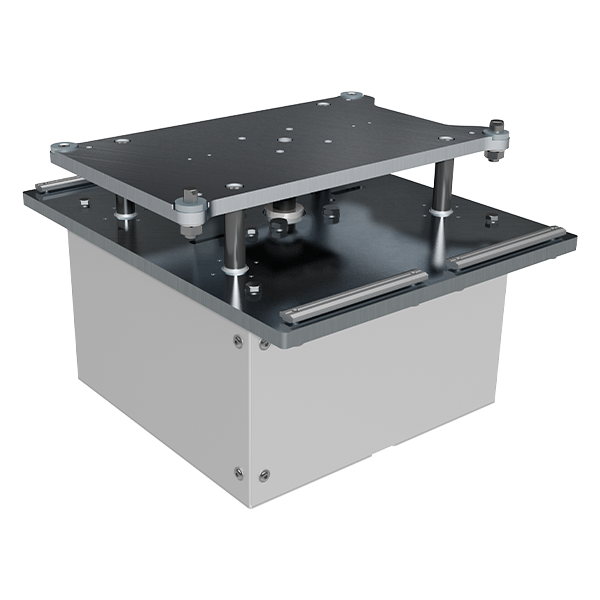

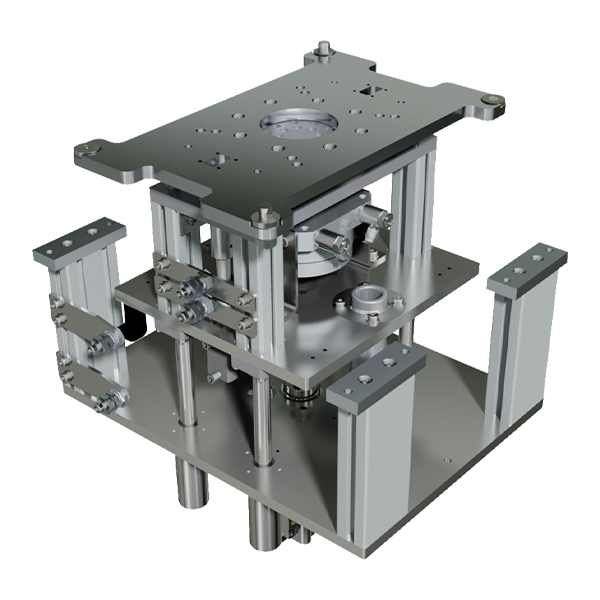

Hub-Indexer

By using a hub indexing station, products are indexed and additionally lifted off the conveyor line. This ensures perfect positioning of the products in the X, Y and Z axes. In addition to pneumatic versions, special designs with electric motorized lifting are also available and the lifting height is always adapted to the required transport task.

Hub rotating indexer (partially / fully automatic)

Hub rotating indexers not only ensure indexing and lift-off with positional accuracy, they also enable the rotation of the workpiece carriers in any direction. Depending on requirements, rotation can be fully automatic or manual and can be locked in any desired position.

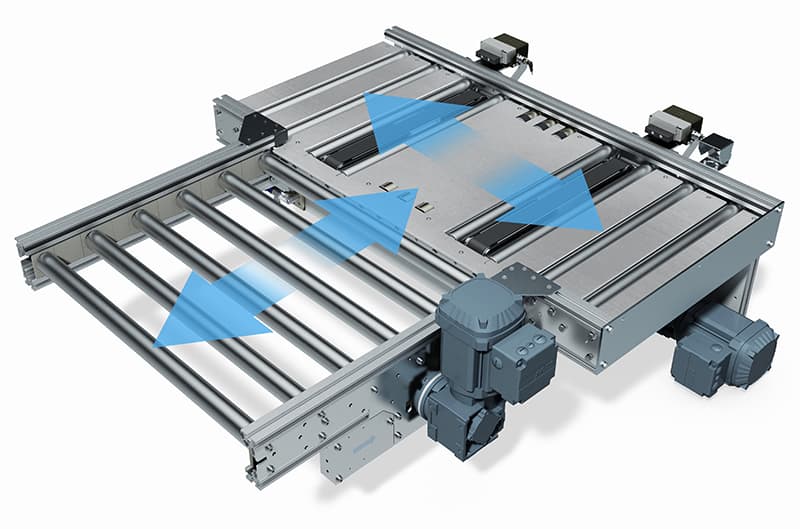

For almost any application

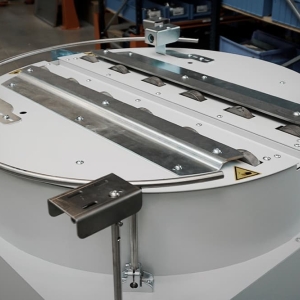

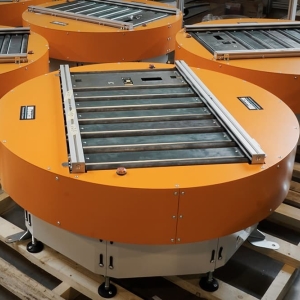

Turning Stations

Turning stations are used to change direction without changing the orientation of the product within the conveyor line.

They are self-sufficient system components and can be integrated into almost any production process. They are driven either by electric motors or pneumatically.

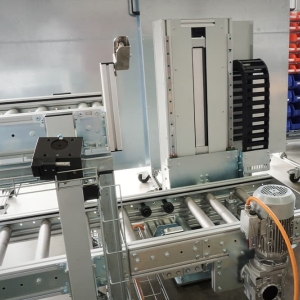

Gentle product transfer and discharge

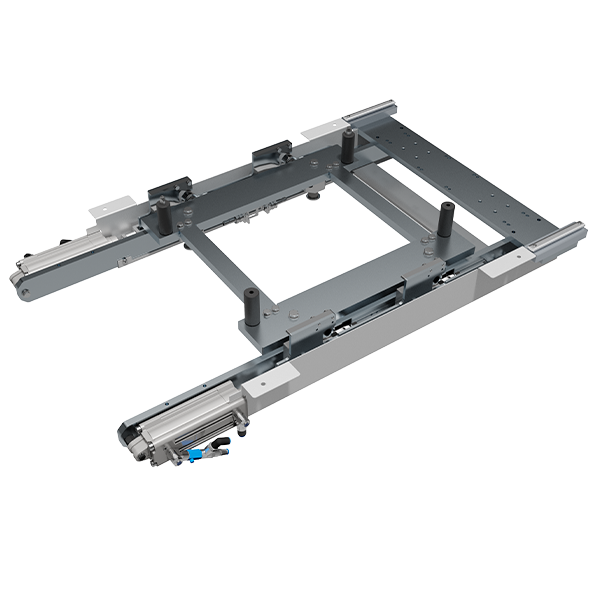

Cross Conveyor

Especially in the area of roller conveyor systems, we have a wide range of modules for transferring or discharging products and workpiece carriers.

These modules, most of which are equipped with timing belts or carrying chains, ensure precise transfer and discharge without affecting the product. Depending on the application, pneumatic and electric motor modules are available for the lifting movement.

Timing Belts

Timing belts ensure safe and gentle transport. The available properties, such as stowability, cut resistance or carryability are almost limitless.

Carrying chains

Carrying chains are characterized by their robust nature and high load capacity. They are particularly insensitive to dirt and have a long service life.

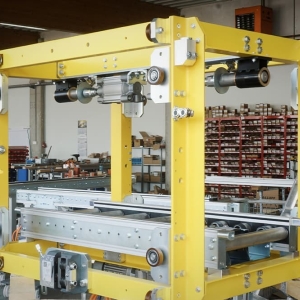

Overcoming height differences easily and flexibly

Hub Modules

Electric or pneumatic hub modules are available for vertical transport in multi-level conveyors.

Whether at the end or within the conveyor line, they can be used to overcome height differences easily and flexibly. The modular design guarantees integration into almost any of our conveyor systems, and the compact design enables use even in confined spaces.

4 pillars for big tasks

Lifts

The 4-pillar lift offers optimal vertical product transport and overcomes even large differences in height.

The modular design of the lift achieves an overall height of up to 8 meters and a transport speed of up to 60 m/min. A variety of safety devices and protective measures ensure safe use in your production.

Sort, separate, push off

Push-Off Modules

Pneumatic push-off units can be designed in any conceivable shape and easily installed on your conveyor system.

Our modular system offers a wide range of standardized modules for sorting, separating, or discharging products from the conveyor line.

Simple instead of complicated

Service-Gates

The installation of service gateways ensures short distances when the conveyor line has to be crossed by people or industrial vehicles.

With their help, complicated routing or elevated sections can be dispensed with in many cases. Service passages are optionally designed as flap or swing modules. They are opened and closed manually, while the opening status is always detected by sensors. Alternatively, a wide variety of staircase crossings are also available for the transition across the conveyor system.

Large weights flexible and safe

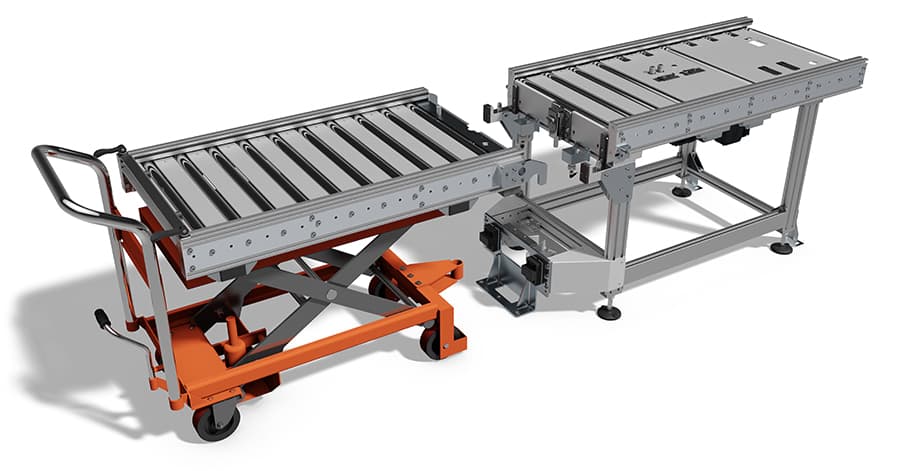

Docking Conveyors

If products are to be fed out of or fed into the conveyor line or the production process, docking shuttles can be used for this purpose.

With their help, even large weights can be moved easily by hand within the factory. Mechanical interlocks ensure a safe transfer between the shuttle and the conveyor system.