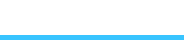

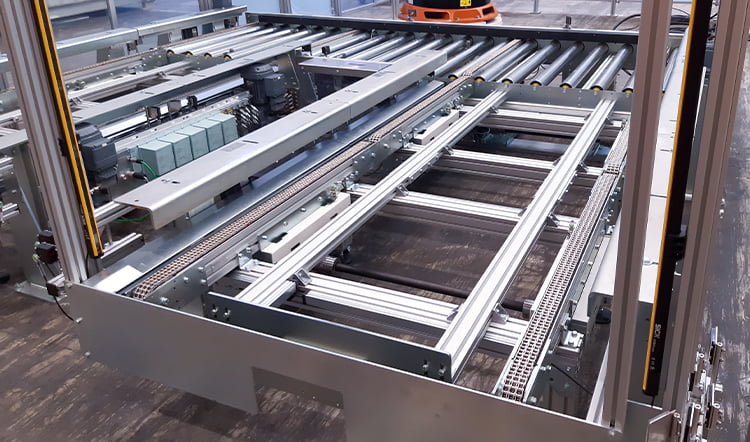

Carrying Chain Conveyor

Effective transport on carrying chains

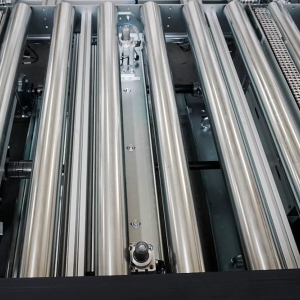

Our carrying chain conveyors are extremely robust and ensure a high level of safety during operation. The resistant roller chains always transport high loads safely and quietly.

Whether double or triple chain, rust and acid resistant or roller chains with special fastening elements, the extensive range offers the right solution for almost every transport task. The chains always run over wear-resistant glide bars which guarantee a long service life. In combination as corner transfer units with roller conveyors or accumulation roller chain conveyors, perfectly coordinated transport concepts are also available for large loads. Contact us, we will be happy to advise you.

Overview

Technical Data

The technical data listed are approximate values for standard specifications of our carrying chain conveyors. For special requirements, our engineers will be happy to assist you and find a solution also for your particular transport task.

- Length

- max. 20.000 mm

- Chain width

- 06B-2 / 08B-3

- Conveying load

- max. 1.500 kg/m

- Drive

- Direct drive, head drive, center drive

- Speed

- max. 25 m/min.

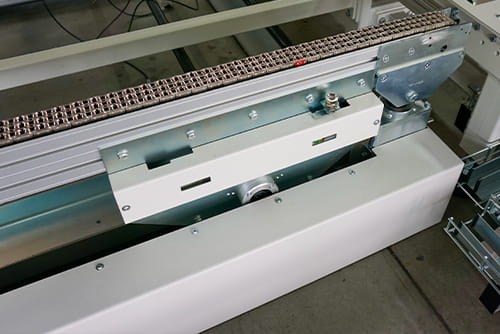

Chassis

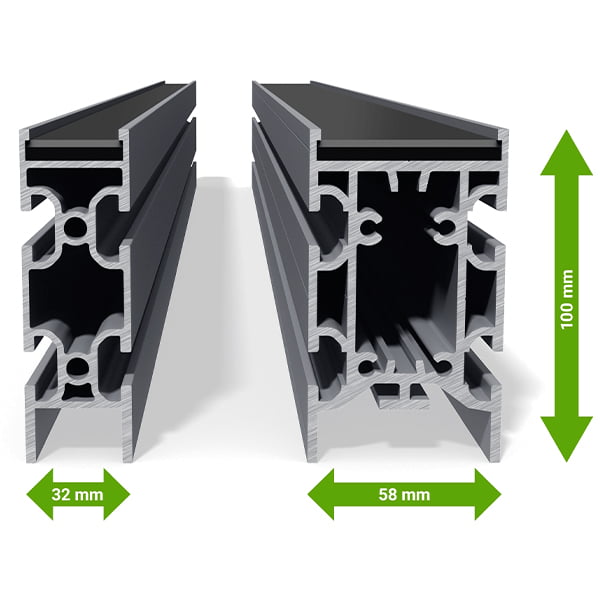

The Basis

The basis of our carrying chain conveyors is always a 100 mm high anodized and torsion-resistant aluminum profile. The two continuous profile grooves on each side offer practical options for mounting attachments such as supports, side guides or sensors.

The aluminum profile is available in two different sizes and is selected to suit the transport task depending on the chain type and load level. The deflection takes place via a sprocket wheel as standard and can be carried out with two smaller rollers arranged one above the other for more compact transfer points in track-to-track arrangements. The carrying chains are always guided quietly on wear-resistant plastic glide bars.

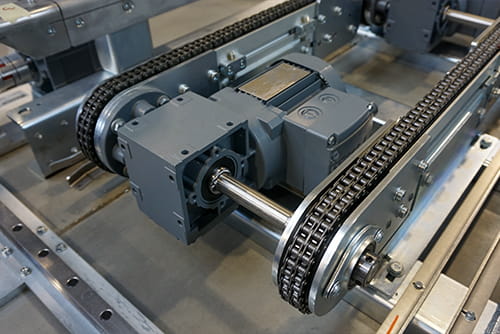

Drive

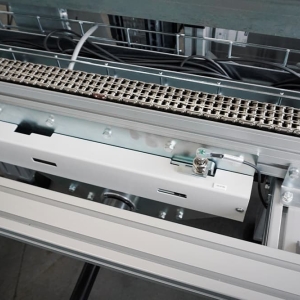

The drive - Unstoppable!

With our efficient drive concepts, our conveyors master every application, no matter how heavy or fast it may be.

The form-fit drive concept enables a slip-free chain drive with a stable chain guide at the same time. If required, the motors can be equipped with forced cooling fan, brake, thermal monitoring and additional frequency control. Whether direct or indirect connection between motor and drive roller - we design the drive according to the installation situation and the desired operating mode. Exactly as it should be. In addition to the drive types listed, there is a wide range of special solutions which we will be pleased to design and supply on request.

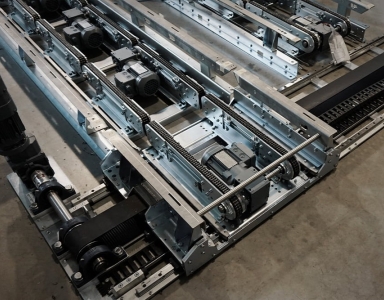

Carrying Chains

Many possibilities - one goal

Carrying chains, also known as roller chains, have a wide range of different properties and are used in industry in many different ways.

Roller chains are characterized by their robust nature and high load capacity. They are largely insensitive to dirt and have a long service life. In addition to the usual straight link plates, the range also includes special designs with flights or special attachment options. Furthermore, special roller chains are available for maintenance-free operation, which can be operated without lubricants.

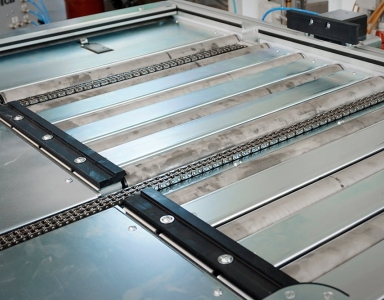

Designs

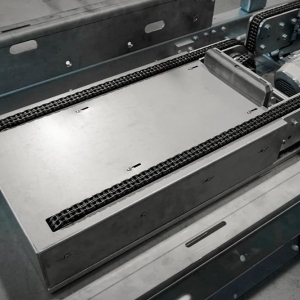

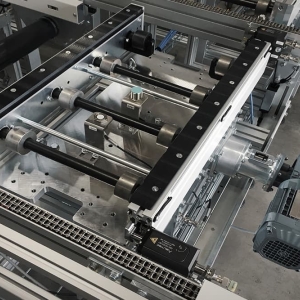

For complex conveyor concepts

In addition to being used as a stand-alone conveyor system, carrying chain conveyors are ideally suited for interlinking with other conveyor systems thanks to their extremely compact as well as resilient design.

Whether as corner transfer units, for transferring out or transferring in on roller conveyors, for example, or accommodated in so-called shuttle systems, highly complex conveying concepts can be easily implemented with carrying chain conveyors.

The conversion of production in the field of electromobility has presented us and our customers with major challenges. With our conveyor concepts, specially developed for the automotive industry, we have met the needs of the industry in good time. For example, we were able to implement effective conveyor systems for transporting large battery cells using carrying chain conveyors.

Accessories

Side guides & supports

Side guides

Our modular system offers you a wide range of different product guides. In addition to the technical versions, we naturally also supply side guides in stainless steel construction for use in hygienic areas.

Versions

- Rigid or adjustable

- Straight or angled

- In desired height

- Height and width adjustable

- Stainless steel construction

- And much more...

Supports

Our conveyors are always delivered with a stable base frame, manufactured from anodised aluminium profiles. The height is individually adjusted to the requirements, and can also be seamlessly adjusted +/- 50 mm after delivery. We’re also happy to advise you in terms of ergonomics for the design of the base frame.

Versions

- Supports with machine feet (fixed)

- with swivel castors

- Height adjustable supports

- Compact central support

- Particularly slim two-legged supports

- Stainless steel construction

- Special supports can be easily produced

Special Equipment

Bunker, funnel, cover etc.

We offer appropriate accessories in order to satisfy the individual requirements for carrying chain conveyor.

Exit chutes in product-specific variations are available. Standard funnels or special funnels especially designed and manufactured according to customer speci- fications. A belt cover for protecting parts to be transported from dirt or as contact protec- tion in hazardous surroundings.

Of course, active add-on parts such as stoppers, switches, pushers and much more are also available! Please contact us, we’ll be happy to advise you!