Workpiece Carrier Systems

The workpiece carrier system for any industrial environment

Flexibility and speed among other things are important for the in-house transport of your products.

The workpiece carrier system easymove... and the extension easymove...Automotive offer transport solutions that are precisely tailored to your production conditions. These are economical and can be implemented in the shortest time.

Whether discharging for offline workstations, transport over several levels or complex links, the possibilities of the easymove... track modules guarantee maximum flexibility for your production planning.

Overview

Technical data

The technical data listed are guide values for standard specifications. For special requirements, our engineers will be happy to assist you and find a solution even for your particular transport task.

- Length

- max. 6.000 mm (p. driven segment)

- Useable width

- min. 250 mm - max. 700 mm

- Conveying load

- 300 kg (p. Workpiece carrier)

- Drive

- Chain drive, 24V Motor roller, King shaft

- Speed

- max. 20 m/min.

One Kit

Many possibilities

An extensive kit is available for the planning and implementation of the easymove... workpiece carrier system

In this way, we can quickly implement efficient solutions to resolve your individual transport tasks. And last but not least, the standardised modules guarantee the trouble free expansion of easymove... even after years. The track modules such as curves, switches, lifts, turning stations and corner converters are just as modular as the numerous add-on parts. That is how your new easymove... grows, linking with the assigned task.

Drive station

90° corner deflection

Switch

Corner converter

Workpiece carrier

Stopper

Indexing station

Lift rotary indexer

Lift

360° turning station

An extensive selection of track components from the easymove... modular system is also available for digital factory planning via the Visual Components software. Learn more

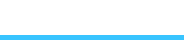

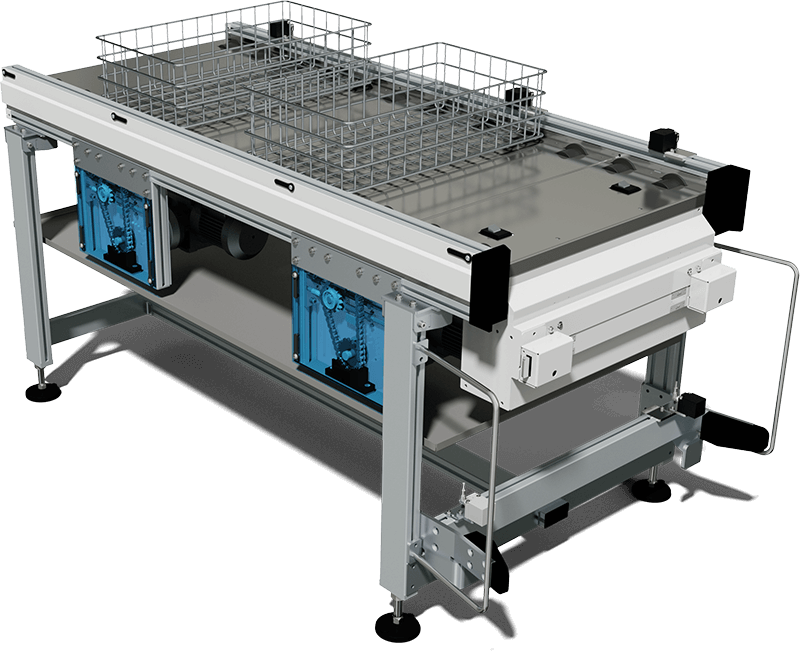

Chassis & Drive

The Basis

The basis of the low-maintenance system is formed by the adjustable friction rollers. They are set in motion by a tangential chain drive. This allows the accumulation pressure and wear to be reduced to a minimum.

The system is driven by an automatically tensioned chain drive. Various motor types, sizes and designs are available for the drive station.

The aluminum profile frame offers lateral profile grooves for easy attachment of further add-on parts and plastic sliding strips are installed on the inside for product guidance. An internal plastic cover protects the roller suspension from external influences and accidental tampering.

Chain drive with internal friction

The economical base with tangential chain drive and adjustable friction rollers.

24V motorized roller for zero pressure accumulation transport

The efficient 24V motor roller provides zero pressure accumulation transport through segmented belt drive.

The easymove... Automotive series was developed to meet special requirements, such as those common in the automotive industry. The Automotive modules have carrying rollers with external friction. This has enabled us to decisively expand the possibilities of the easymove... system.

Chain drive with external friction

Developed for the automotive industry. External friction allows the rollers to be adjusted conveniently on the outside.

King shaft with external friction

The low-maintenance king shaft also offers accessibility from the outside and low noise.

Product examples

The modular construction kit of the easymove... workpiece carrier system has a wide range of practical components to optimize your production. Whether with lifts over several levels, solutions for offline workstations or complex interlinking - the possibilities are almost unlimited. We always plan and design easymove... to suit the transport task at hand.

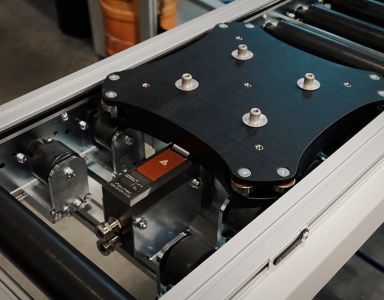

Positioning

Stop and index

Workpiece carrier

The connection between your product and the easymove... transport system is the Workpiece carrier. On request, the standardized base frame can be equipped with a top plate and product-specific holders.

Stopper

A wide range of different stoppers is available for separating the products. This means that specific and gentle stopping of the workpiece carriers is possible without any problems in all weight and speed ranges. In addition to the usual pneumatic operation, electric stoppers are also available.

Indexers

easymove... enables an exact alignment of your products due to its indexing and positioning units. Optionally, the workpiece carriers can be lifted, rotated or staked.

Carrying Rollers and Curves

Once in movement - it stays that way

Carrying rollers:

We manufacture carrying rollers for every field of application. We offer standard roller diameters from 50 to 88 mm. When selecting rollers, there are of course not only different diameters, materials and types of coating available. Thanks to the many years of experience of our employees and an extensive portfolio, we always find the right solution for every transport task.

90° corner deflection:

The 90° corner deflection does not require a separate drive. The workpiece carrier is gracefully deflected 90° by an arc segment without losing its original alignment.

Switch:

Switches are used to move the workpiece carrier from main lines to secondary lines. The swivel arm is moved into position electrically, pneumatically or by the workpiece carrier itself.

The automotive modules have support rollers with external friction. This design guarantees optimum accessibility of the drive system. The friction of each roller can be adjusted conveniently and precisely from the outside. Another advantage of the external friction is the protection of the relevant components against dirt and moisture.

The optimized design of the easymove... Automotive rollers enables a wide range of different designs. This offers a wide range of options for implementing special system concepts. For example, ground disc rollers can be used for the direct transport of products. Rollers with flanges are used to transport washing baskets or wire baskets.

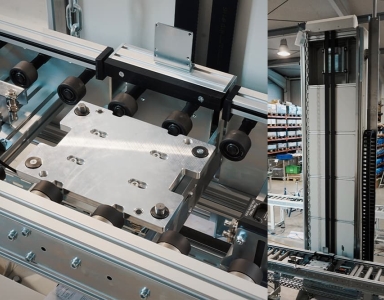

Workpiece Carrier

High End

The workpiece carrier can be as individual and complex as the conveyor itself.

The centerpiece of a workpiece carrier system is the workpiece carrier itself. It is the direct connection between the workpiece and the roller conveyor. The design ranges from a simple basic body to structures with a top plate to complex constructions, specially adapted to the respective workpiece. The right workpiece carrier is always developed for every product and every transport task. This ensures that your products pass through production precisely and safely.

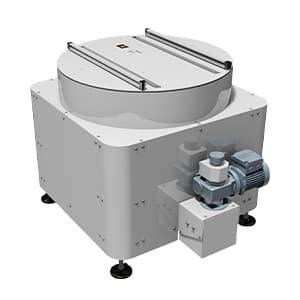

Digital factory planning

Start now with the workpiece carrier system easymove... and Visual Components for your digital factory planning.

As the first fully-fledged workpiece carrier system in Visual Components' eCatalog, easymove... significantly expands the possibilities of the software. The extensive selection of track components such as curves, switches, lifts, turning stations as well as stopper and indexing units offer users endless possibilities for layout design.

For more information visit the Website of Visual Components and find out what possibilities the software might have for your digital factory planning.