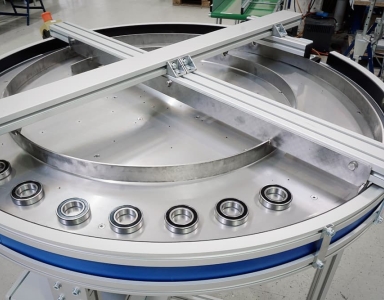

Storage Systems

When things need to run like clockwork

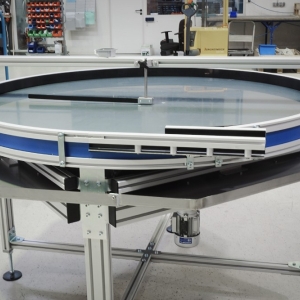

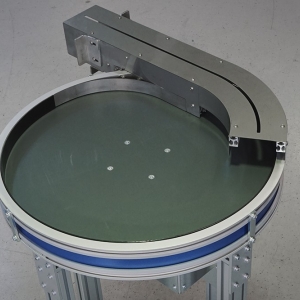

Rotary accumulation tables are the perfect solution for gently storing, buffering and separating of rotationally symmetrical components and products.

Depending on requirements, they buffer products upstream or downstream of a transport or manufacturing process. The high-quality and low-maintenance design guarantees long-lasting operation. Our rotary accumulation tables have proven themselves thousands of times in the industry and thus become a reliable component, also in your production.

Overview

Technical Data

The technical data listed are guide values for standard specifications of our rotary accumulation tables. For special requirements, our engineers will be happy to assist you and find a solution even for your particular transport task.

- Diameter

- min. 600 - max. 2000 mm

- Conveying load

- max. 250 kg

- Drive

- three-phase gearmotor incl. slipping clutch

- Speed

- 1 - 2 rpm.

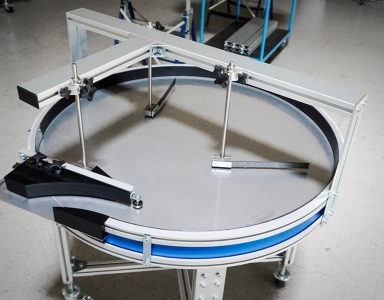

Chassis

The basis

In the standard version, the base frame and chassis of our rotary accumulation tables are made of anodized aluminum profiles. The base frame offers plenty of space between the supports for electrical components such as frequency controllers, motor protection switches and other components. Also, funnels and oil pans for collecting liquids can be installed under the rotary tables. Machine feet and swivel castors can be adjusted in height by +/- 50 mm at any time and the latter ensures a mobile unit. For use in hygienic areas, we also manufacture base frames, chassis and plates completely in stainless steel.

Features:

- high-quality construction

- fully customizable

- Low maintenance and durable

- also in stainless steel construction

- short delivery times

Product examples

Rotary accumulation tables must always be adapted to the respective product. Due to the many years of experience of our employees, whether in the engineering or the subsequent manufacturing, we realize rotary accumulation tables in the shortest possible time. Talk to us, tell us about your project.

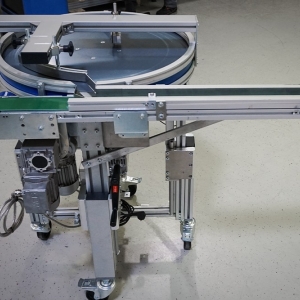

Drive

Compact & robust

Our rotary accumulation tables feature a compact drive concept.

The drive is provided by a three-phase geared motor, which ensures the necessary drive torque. Between the drive unit and the plate there is an appropriate slip clutch to protect the motor.

Depending on your requirements, the drive can be equipped with a frequency controller, motor protection switch and other electrical components. Of course, solutions for use in hygienic areas are also available. Contact us, we will be happy to advise you.

Plates

For every application

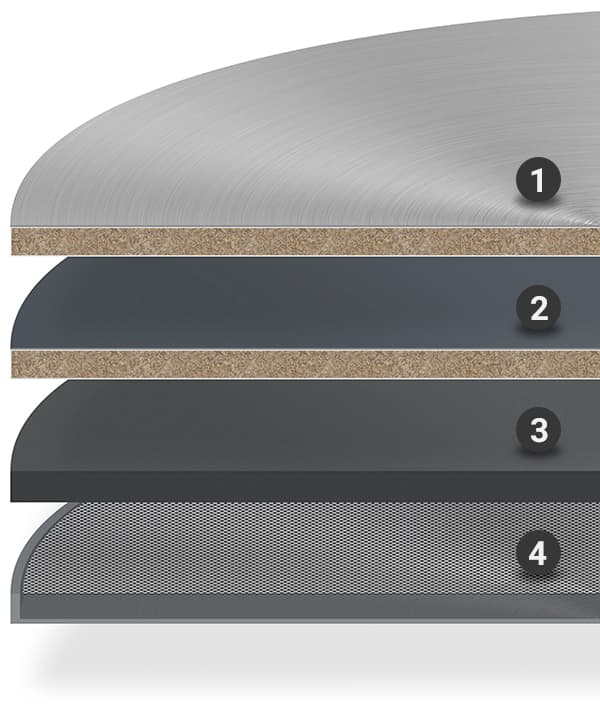

The most important component of a rotary table is its plate.

The plate forms the direct connection to your product and can be supplied in various materials with different surface finishes. We manufacture rotary accumulation tables in diameters from 600 mm to 2000 mm. Our modular construction kit includes four standardized plates with different specifications.

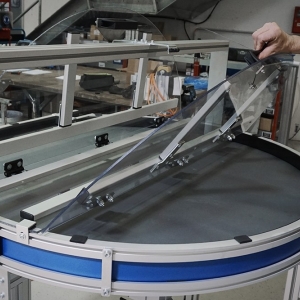

Versions:

- Wooden plate covered with stainless steel

- Wooden plate with plastic coating

- Solid PVC

- Perforated stainless steel plate with integrated oil pan and outlet

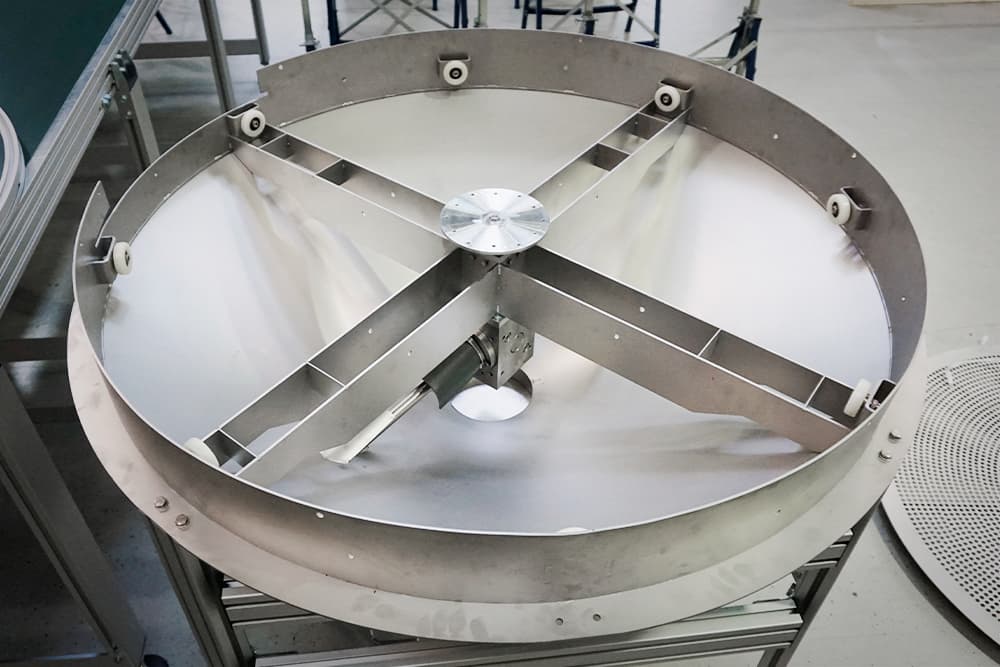

Feeding-in & ejecting-out

Simple principle - highly effective

Depending on the application of the rotary accumulation tables, various Feeding-in & ejecting-out operations are available.

These transfer points are individually adap- ted to your requirements and components. Our employees have many years of expe- rience in this area, thus guaranteeing the best possible results. In addition, a version without feeding-in/ejection is available if these are not required.

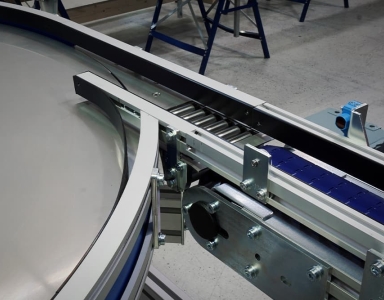

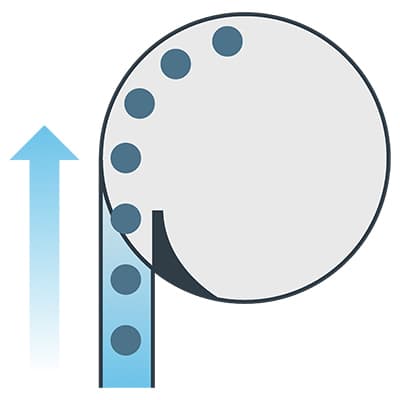

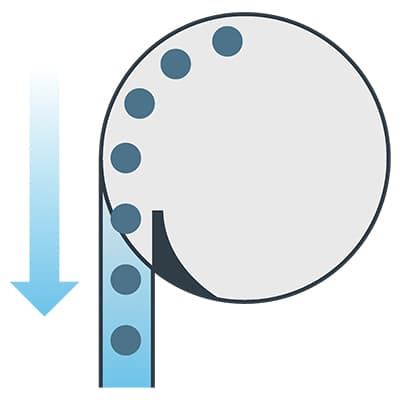

Feeding-in

If the accumulation table is located at the end of a transport line, even non-round components and products can be stored and buffered without any problems. The products can be fed directly onto the accumulation table via chutes or via an infeed/outfeed passage. At the transfer points from conveyor to accumulation table, rollers or roller strips are used depending on the transport task. They enable the products to be fed onto the rotary accumulation table without any problems.

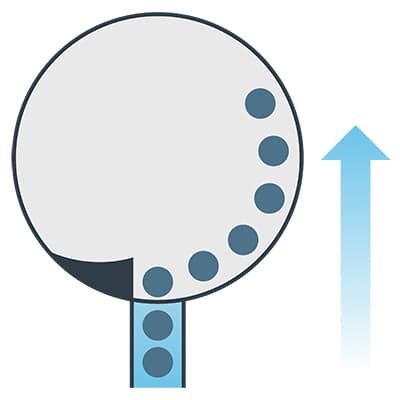

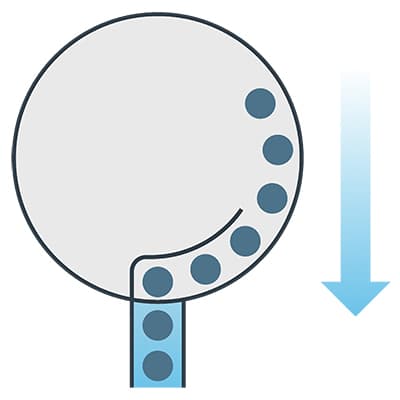

Ejecting-out

Adjustable product guides made of plastic or sheet steel are used to guarantee an orderly material flow during ejection. In addition, controlled stopper systems can be installed for cycle-time-optimized diverting. Particularly when it comes to outfeed, you benefit from the many years of experience of our employees. No accumulation table leaves our factory without having proven a faultless and perfect ejection process in extensive test runs.

Feeding-in tangential

Feeding-in central

Ejecting tangential

Ejecting central

Accessories & Equipment

Designed one step ahead

From suitable conveyor technology to sensor and control equipment, height-adjustable supports and safety-related extensions such as covers and housings. Our modular system also offers a wide range of practical accessories and equipment components for our rotary accumulation tables. Should our modular system not provide the desired solution, a professional team of engineers is ready to solve your special transport task.

Standard accessories include:

- Supports (also height adjustable)

- Active infeed / ejection

- Infeed/ejection incl. conveyor system

- Enclosures & Covers

- Sensors

- Light grid & Light barriers

- And much more...

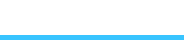

Stainless Steel

An essential material

Especially in hygienically sensitive areas, the use of conveyor systems and machines is associated with special challenges.

As a specialist for conveying technology, we naturally also offer you individual solutions when it comes to logistical processing in the food, cosmetics and pharmaceutical industries.

Thanks to our modular construction systems, we can draw on a large portfolio of the most diverse conveyor systems in stainless steel construction. Thanks to many years of experience in the field of stainless steel processing, we can implement systems that meet your special requirements. In this way, we manufacture and supply the right conveyor technology for almost any transport task, and always with an attractive price-performance ratio.