Storage systems

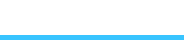

One step ahead with linear accumulation tables

Linear accumulation tables are a simple and cost-effective way to maintain a continuous flow of material.

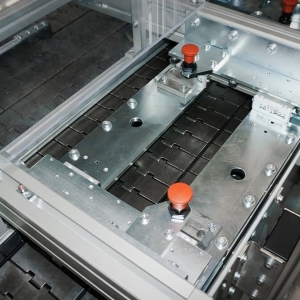

With our linear storage tables you are always one step ahead of the competition! Due to the rectangular design of the linear accumulation tables, they make efficient use of the available space. In addition to rotationally symmetrical parts such as gears, ball bearings, cans and turned parts, non-round parts can also be transported and buffered by using workpiece carriers.

Overview

Technical Data

The technical data listed are guide values for standard specifications of our linear accumulation tables. For special requirements, our engineers will be happy to assist you and find a solution also for your special transport task.

- Dimensions (WxL)

- 2400 - 6000 mm

- Conveying load

- max. 800 kg

- Drive

- Three-phase geared motor

- Output rate

- max. 240 Parts p. min.

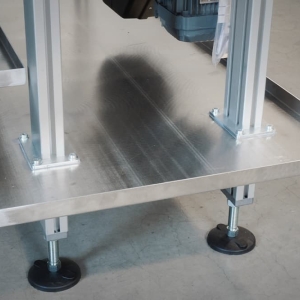

Chassis

The Basis

In the standard version, the base frame and chassis of our linear accumulation tables are made of anodized aluminum profiles. The base frame offers plenty of space in the lower area for electrical components such as frequency controllers, motor protection switches and other control components. Covers and housings are designed and manufactured on request. Oil pans for collecting liquids can also be installed under the storage tables. Machine feet and swivel castors are adjustable in height by +/- 50 mm at any time and the latter ensures a mobile unit.

Eigenschaften:

- high-quality construction

- Customizable

- Low maintenance and durable

- short delivery times

Product examples

Linear accumulation tables must always be adapted to the respective product. Thanks to the many years of experience of our employees, whether in design or subsequent production, we realize accumulation tables in the shortest possible time. Please contact us, we will be pleased to advise you.

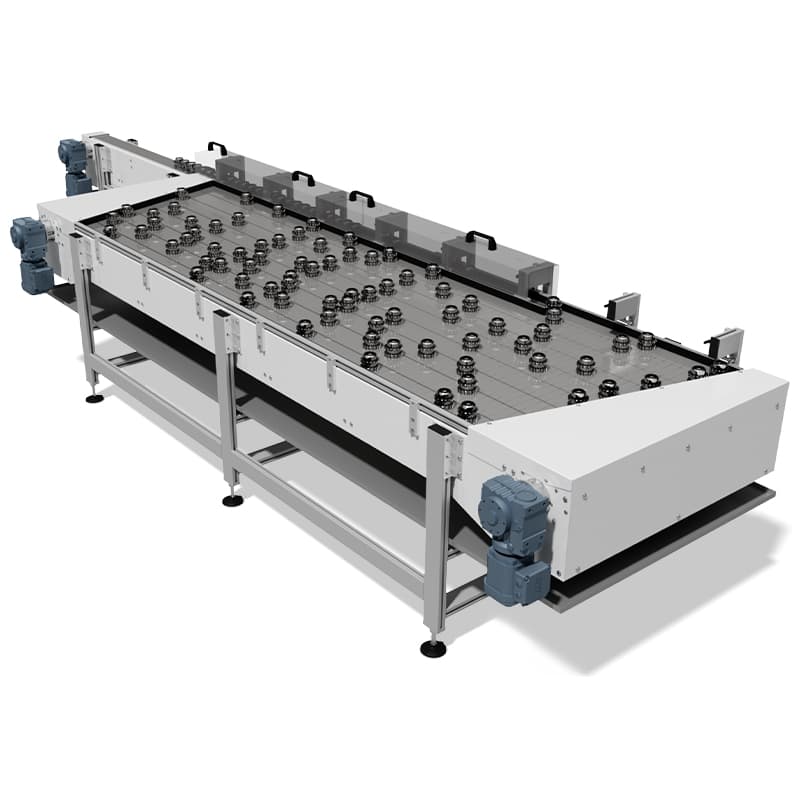

Drive

Compact & robust

Our linear accumulation tables feature a compact and robust drive concept.

Depending on the design and transport task, various drives or drive types are available. The motors of our drive units offer an almost vibration-free drive with high efficiencies and excellent running characteristics. Thanks to their compact aluminum housing, they always impress with a low dead weight. Last but not least, the motors of our drive units offer maintenance-free operation thanks to their practical lifetime lubrication.

Of course, drive units with frequency controllers, motor protection switches and other electrical components are also available for our linear accumulation tables.

Designs

Many possibilities - One goal

We always design and manufacture linear accumulation tables to suit the required transport task. Are products to be fed to a production process in an equalized and cycle-time-optimized manner, buffered within a transport line or stored at the end of a production run? For these and other application-specific requirements, a large number of different designs and functionalities are available. Of course, product characteristics and desired cycle performance also influence the design and the materials used. The modular design paired with tailor-made solutions guarantees the excellent adaptation of the accumulation tables to the transport task at hand. We see the customer-specific applications as a challenge for demand-oriented consulting, production and delivery. Please contact us, we will be pleased to advise you.

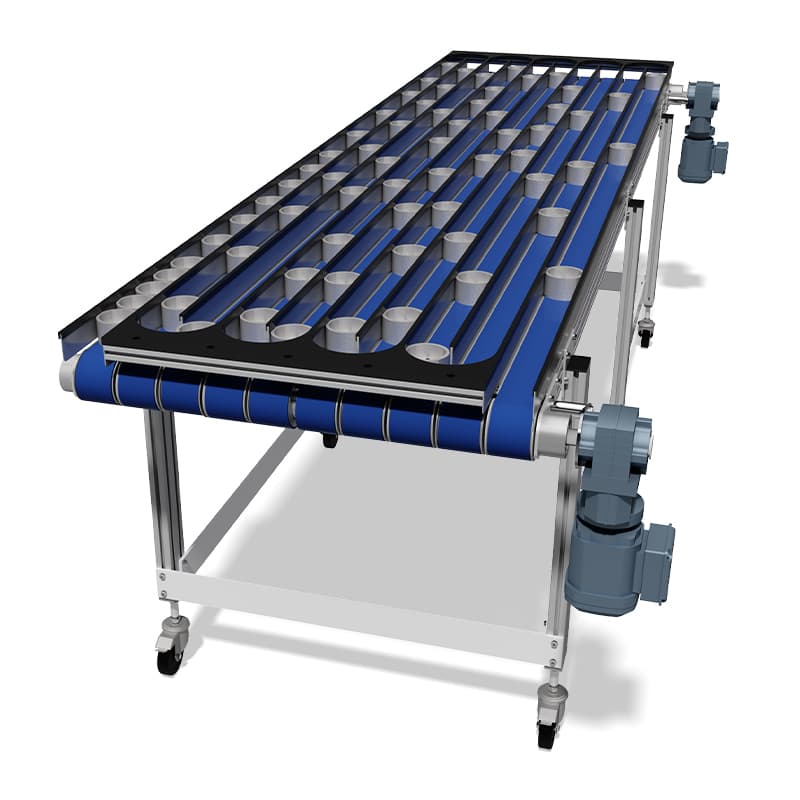

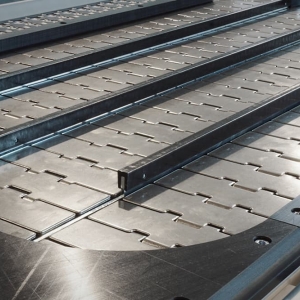

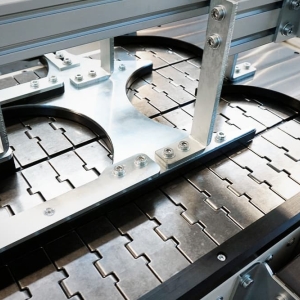

Belts & Chains

For optimal function

Whether hardened steel chains, plastic chains or textile belts, our modular construction kit has different concepts and functionalities ready for every application and design.

In accordance with the respective transport task and in order to ensure optimum function, the linear as well as surface accumulation tables are precisely matched to the requirements of the components to be transported.

The following belts and chains are available:

- Belts made of PU, PVC etc.

- Timing belts

- Plastic modular chains (open or closed)

- Curved plastic hinged chains

- Hinge chains made of steel & stainless steel (hardened)

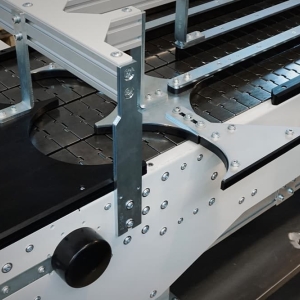

Feeding In & Out

Orderly chaos

Whether for infeed or outfeed, our linear accumulation tables ensure order when things get chaotic! When feeding out, they separate placed parts and feed them into the production process in an orderly manner or use the storage area as a buffer zone when feeding in or feeding through.

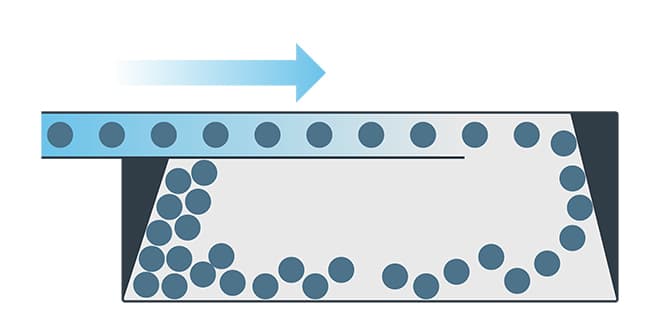

Feeding-in / storing

When feeding-in, the storage area is used to collect the delivered parts.

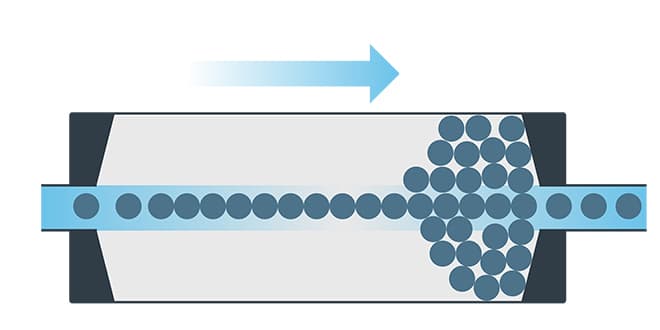

Guiding through / buffering

Within the production line, the systems are used as buffers and prevent, inter alia, process-related interruptions.

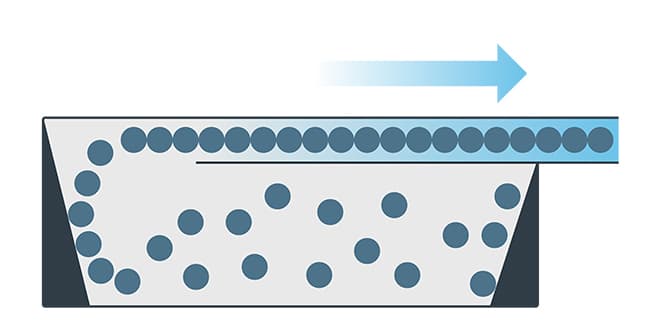

Ejecting / separating

When ejecting, the jumble of parts are buffered, separated and added to the production process in an orderly manner.

Accessories & Equipment

Thought one step further

From suitable conveyor technology to sensor and control equipment, height-adjustable supports and safety-related extensions such as covers and housings.

Our modular system also offers a wide range of practical accessories and equipment components for our linear accumulation tables. Should our modular system not provide the desired solution, a professional team of engineers is ready to solve your special transport task.

Standard accessories include:

- Supports (also height adjustable)

- Active in-/outfeed

- Infeed/outfeed incl. conveyor system

- Housings & Covers

- Sensors

- Light grid & Light barriers

- Oil pans

- And much more...